- Have any questions?

- +86 15953537010

- admin@wepower-electronic.com

- Home

- Level Switch

- Vibration Fork Level Switch

- Vibration Fork Type Level Switch

Vibration Fork Type Level Switch

The vibration fork type level switch does not require any calibration, is easy to install and operate, used as high and low level switches for various liquids.

![]()

Features Of Vibration Fork Type Level Switch:

Vibration Fork Type Level Switch does not require any calibration, is easy to install and operate properly as a high, low level Switch a wide range of liquids . Our WPX503 Vibration Fork type Level Switch has the high reliability and performance , which is ideally used in water , solvents , chemical, food and beverage ,etc .

From the appearance of vibrating fork switch, it is exquisite, small and compact, from process connecting , there are widely used thread type , flange connecting , and tri-clamp type which is recommended for food or hygienic fields ; From the fork types , there are short small fork ( fork length is 45mm) and standard 100mm fork length.

Working Principle Of Vibration Fork Type Level Switch:

The tuning fork’s base is equipped with two piezoelectric crystals that allow it to vibrate at a resonant frequency. The tuning fork’s frequency and amplitude will alter when the liquid level switch’s fork comes into touch with the medium. An intelligent circuit will detect and process these variations in the tuning fork’s liquid level switch, converting them into a switch signal.

| Measure Medium | Liquid |

| Vibrational Frequency | 350/1000HZ |

| Accuracy | ±2mm |

| Fork Length | 40mm or 100mm |

| Measuring Length | 40-1000mm |

| Ambient Temperature | -30-80℃ |

| Operation Temperature | -30-150℃ |

| Repeatability | ±2mm |

| Indication Method | LED |

| Power Supply | 24V DC |

| Power | 1 W |

| Signal Output | SPDT/PNP/NPN/NAMUR |

| Body Material | Stainless steel |

| Pressure Range | -98KPa-3MPa |

| Wetted material | SS304/SS316 |

| Process Connecting | Thread, Tri-clamp |

| Electrical Interface | Hersman Joint / Aviation Joint |

![]()

Installation Guidance

Installation method of compact fork type level switch:

Before installation, you should reconfirm whether the model meets the environmental requirements of the site (such as: process pressure, process temperature, chemical properties of the medium, etc.) to ensure that the instrument can be used normally after installation.

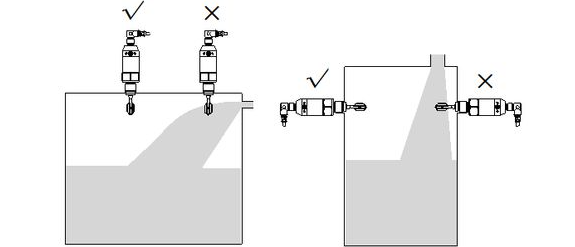

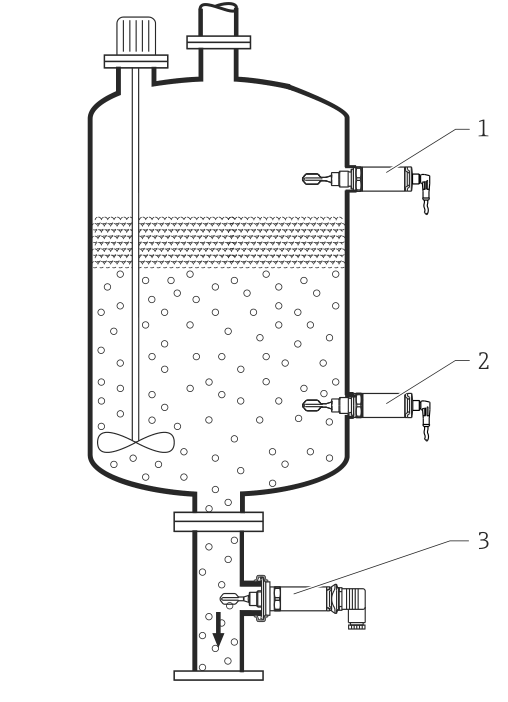

Generally, the compact fork type level switch can be installed in any position as required, and can be installed horizontally, vertically or obliquely. But when the measured medium is relatively viscous, in order to reduce or avoid the phenomenon of hanging materials, the meter should be installed vertically.

- Installation Direction

When installing the compact tuning fork type level switch, the fork body surface and the liquid lifting or flow should be kept in the same direction, so as to avoid the measurement error caused by the resistance of the medium to the fork body.

2.Avoid The Inlet

When choosing the installation position of the compact tuning fork liquid level switch, avoid measurement errors caused by installation at the feed inlet position, or even damage to level switch .

![]()

![]()