- Have any questions?

- +86 15953537010

- admin@wepower-electronic.com

- Home

- Tempereaure Measurement

- Thermocouple Sensor

- Thermocouple Sensor K Type

Thermocouple Sensor K Type

Thermocouple Sensor K Type is the most widely used thermocouple at present, and its usage is the sum of other thermocouples. Thermocouple sensor K type has the advantages of good linearity, large thermoelectric potential, high sensitivity, good stability and uniformity, strong anti-oxidation performance, and low price. It can be used in an oxidizing inert atmosphere.

![]()

What’s The Working Principle Of Thermocouple Sensor K Type?

The Thermocouple Sensor K Type is a thermometal thermocouple that combines two distinct metals to produce an induced voltage that varies with temperature. Electric potential variations are created on both ends of two distinct metal wires as a result of temperature changes. Both the extension wire and the thermocouple have positive and negative poles. In a variety of production processes, thermocouple sensor K type directly monitors the temperature of liquids, steams, gases, and other fluids as well as solid surfaces between 0 and 1100°C.

Applications

- Chemical and petrochemical industries

- Machinery, plant and tank measurement

- Oil and gas industries

- Power and utilities

- Pulp and paper

Parameters:

| Category | Code | Graduation Mark | Extermal diameter of tube(mm) | Common temperature (°C) | High operating temperature (°C) | Allowable deviation | |

| Measuring range (°C) | Allowable difference | ||||||

| Platinum rhodium 10-platinum | WRPK | S | ≥Φ3 | 1100 | 1200 | 0-1200 | ±1.5°C or ±1.5%t |

| Nickel-chromium-copper-nickel | WREK | E | ≥Φ3 | 600 | 700 | 0-700 | ±2.5°C or ±0.75%t |

| Nickel-chromium-nickel silicon | WRNK | K | ≥Φ3 | 800 | 950 | 0-900 | ±2.5°C or ±0.75%t |

| Copper-copper nickel | WRCK | T | ≥Φ3 | 350 | 400 | Less than -200 | Unspecified |

| -40-350 | ±0.75%t | ||||||

| Iron-copper nickel | WRFK | J | ≥Φ3 | 500 | 600 | 0-600 | ±2.5°C or ±0.75%t |

![]()

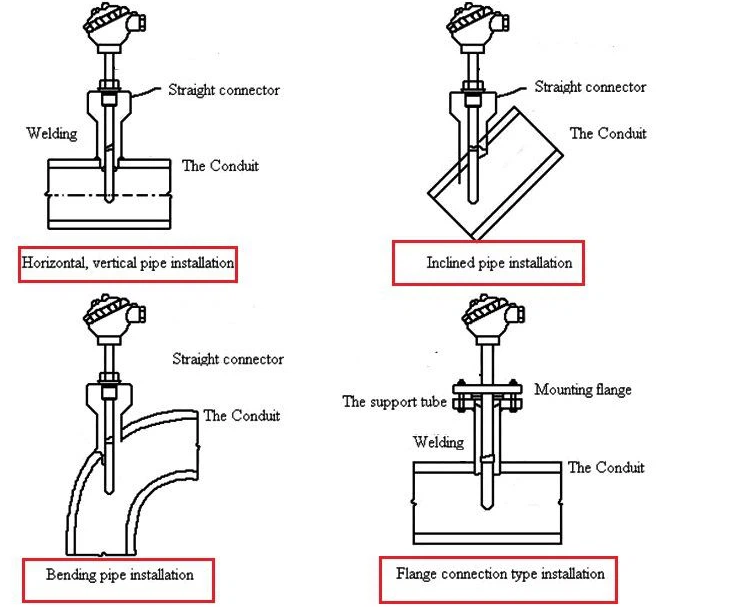

Installation Guidance:

![]()