- Have any questions?

- +86 15953537010

- admin@wepower-electronic.com

- Home

- Level Meter

- Submersible Level Meter

- Submersible Tank Level Sensor

Submersible Tank Level Sensor

The Submersible Tank Level Sensor is suitable for the level measurement of various media in petrochemical, metallurgy, electric power, pharmaceutical, water supply and drainage, environmental protection and other systems and industries.

![]()

What Occasions Are Submersible Tank Level Sensor Suitable For?

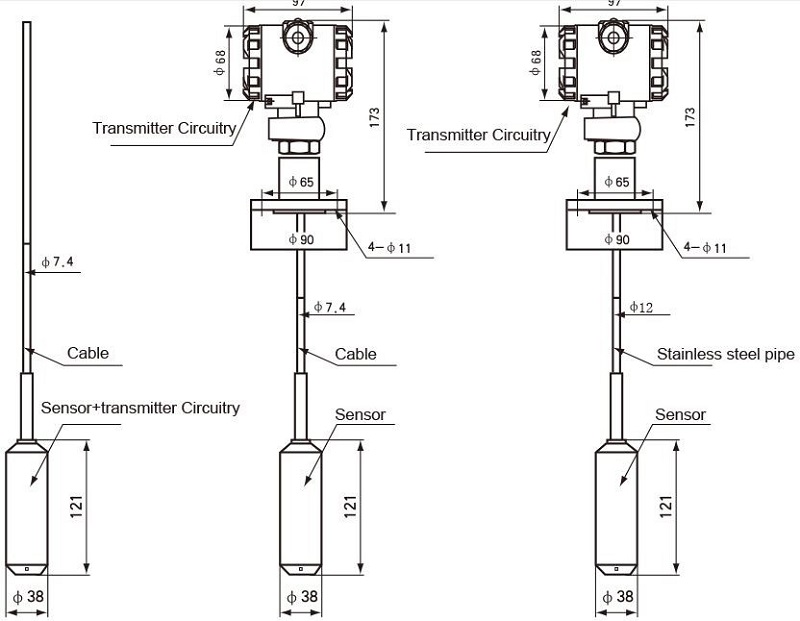

Submersible Tank Level Sensor is suitable for the level measurement of various media in petrochemical, metallurgy, electric power, pharmaceutical, water supply and drainage, environmental protection and other systems and industries. The exquisite structure, simple adjustment and flexible installation provide convenience for users to use easily. Standard signal output modes such as 4-20mA, 0-5v, 0-10mA, etc. The submersible tank level sensor can be selected by the user according to their needs. The stainless steel sensor of the input type liquid level gauge is equipped with an extensible polyurethane shell material cable. The submersible tank level sensor can choose a sensor with a heavy anchor. This kind of input type liquid level gauge is used in fluctuations Or in the Rapid liquid occasion.

Submersible Tank Level Sensor is made of advanced isolation diffused silicon sensitive elements. The submersible tank level sensor can be directly put into the container or water body to accurately measure the height from the end of the water level gauge to the water surface, and the water level value can be externally passed through 4-20mA signal Output.

Working Principle Of Submersible hydrostatic level transmitter:

The submersible liquid level transmitter adopt the principle of static pressure measurement; when the liquid level transmitter is put into a certain depth in the measured liquid, the pressure formula on the sensor’s front surface is:

Ρ = ρ .g.H + Po where:

P: Pressure on the face of the transmitter

Ρ: Density of the measured liquid

G: local acceleration of gravity

Po: atmospheric pressure on the liquid surface

H: the depth of the transmitter into the liquid

At the same time, the pressure of the liquid is introduced into the positive pressure cavity of the sensor through the gas-conducting stainless steel, and then the atmospheric pressure Po on the liquid surface is connected to the negative pressure cavity of the sensor to offset the Po on the back of the sensor, so that the pressure measured by the sensor is: ρ. gH, obviously, by measuring the pressure P, the liquid level depth can be obtained.

![]()

![]()

| Model | KSL Submersible Tank Level Sensor |

| Measuring Range | 0~0.5~500m H2O |

| Power supply | 12~36VDC (Standard 24VDC) |

| Output Signal | 4~20mA; 0~5V; 1~5V; 0-10V; RS485 |

| Accuracy | 0.2%F.S; 0.5%FS |

| Response Time | ≤1ms (up to 90%FS) |

| Long-term Stability | ±2F.S/Year |

| Medium Temperature | -20~85℃ |

| Working Temperature | -40~80℃ |

| Overload Capacity | 200%F.S |

| Insulation Resistance | 100MΩ/250VDC |

| Sensitivity Drift | ±2%F.S |

| Zero Drift | ±2%F.S |

| Protection | IP68 |

| Measurin Medium | Various medium which is compatible with SS304 |

| Mechanical Vibration | 20g (20~5000Hz) |

| Impact | 100g (11MS) |

| Material | Junction box: Low content Cu-Al alloy

Probe: Stainless steel Cable: Polyurethane cable |

| Application | Static liquid level, Liquid tank, Sewage water, Well, Lake, etc. |

![]()

![]()