- Have any questions?

- +86 15953537010

- admin@wepower-electronic.com

- Home

- Level Meter

- Submersible Level Meter

- Submersible Hydrostatic Level Transmitter

Submersible Hydrostatic Level Transmitter

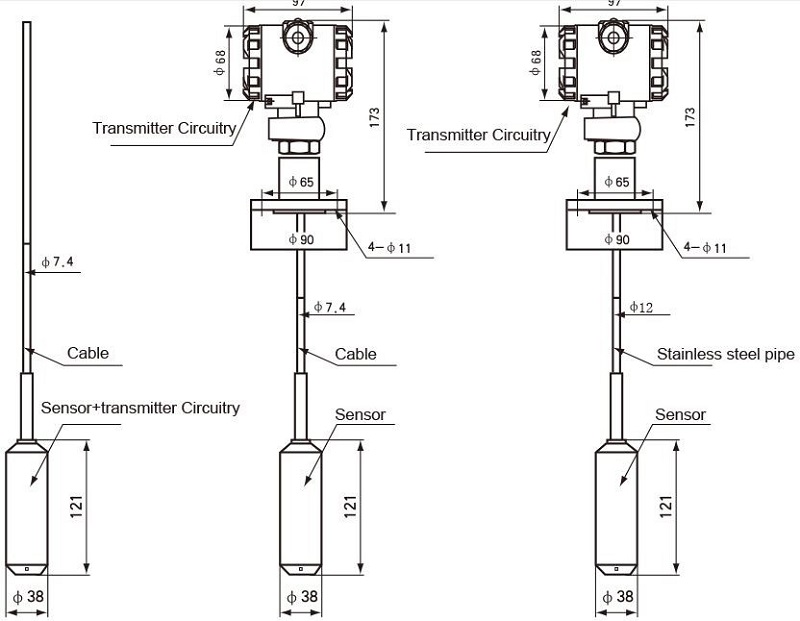

Submersible hydrostatic level transmitter has good stability and high precision, the stainless steel probe sensor can be directly input into the measured medium, which is quite convenient to install and use.

![]()

Features Of Submersible Hydrostatic Level Transmitter:

Submersible Hydrostatic Level Transmitter has good stability and high precision, thie stainless steel probe sensor can be directly input into the measured medium, which is quite convenient to install and use.

Submersible hydrostatic level transmitter has solid structure, no moving parts, high reliability, long service life. High-precision measurement can be made from water, oil to thick pastes, and is not affected by the foaming, deposition, and electrical characteristics of the measured medium. The submersible hydrostatic level transmitter has power reverse polarity protection and overload current limiting protection.

Working Principle Of Submersible hydrostatic level transmitter:

The submersible liquid level transmitter adopt the principle of static pressure measurement; when the liquid level transmitter is put into a certain depth in the measured liquid, the pressure formula on the sensor’s front surface is:

Ρ = ρ .g.H + Po where:

P: Pressure on the face of the transmitter

Ρ: Density of the measured liquid

G: local acceleration of gravity

Po: atmospheric pressure on the liquid surface

H: the depth of the transmitter into the liquid

At the same time, the pressure of the liquid is introduced into the positive pressure cavity of the sensor through the gas-conducting stainless steel, and then the atmospheric pressure Po on the liquid surface is connected to the negative pressure cavity of the sensor to offset the Po on the back of the sensor, so that the pressure measured by the sensor is: ρ. gH, obviously, by measuring the pressure P, the liquid level depth can be obtained.

![]()

![]()

| Model | KSL Submersible Hydrostatic Level Transmitter |

| Measuring Range | 0~0.5~500m H2O |

| Power supply | 12~36VDC (Standard 24VDC) |

| Output Signal | 4~20mA; 0~5V; 1~5V; 0-10V; RS485 |

| Accuracy | 0.2%F.S; 0.5%FS |

| Response Time | ≤1ms (up to 90%FS) |

| Long-term Stability | ±2F.S/Year |

| Medium Temperature | -20~85℃ |

| Working Temperature | -40~80℃ |

| Overload Capacity | 200%F.S |

| Insulation Resistance | 100MΩ/250VDC |

| Sensitivity Drift | ±2%F.S |

| Zero Drift | ±2%F.S |

| Protection | IP68 |

| Measurin Medium | Various medium which is compatible with SS304 |

| Mechanical Vibration | 20g (20~5000Hz) |

| Impact | 100g (11MS) |

| Material | Junction box: Low content Cu-Al alloy

Probe: Stainless steel Cable: Polyurethane cable |

| Application | Static liquid level, Liquid tank, Sewage water, Well, Lake, etc. |

![]()

▲ Since the bottom of the tank or bilge is easy to deposit sludge, oil residue, etc., it is recommended to leave the measuring probe at a certain height from the bottom of the tank (bilge) to prevent debris from blocking the probe.

▲When the medium fluctuates greatly and the cable is long, the probe should be fixed with a sleeve to prevent the probe from swinging and affecting the measurement accuracy.

▲When the transmitter is installed on the side, the bending radius of the cable should be greater than 10 cm to avoid excessive bending and damage to the cable.

▲The ground terminal of the transmitter should be reliably grounded, and the power shield wire should be connected to it.

▲When measuring explosive dangerous goods, the relevant regulations in GB3836.1-83 “General Requirements for Explosion-proof Electrical Equipment for Explosive Environments” and GB3836.4-83 “Intrinsically Safe Circuits and Electrical Equipment “i”” must be strictly followed. installation.

▲When the level gauge is installed in a static deep well or pool, usually a steel pipe with an inner diameter of Φ45mm (several small holes are punched at different heights so that the water can enter the pipe smoothly) is fixed in the water, and then the transmitter is placed in the steel pipe. be usable.

▲When measuring the liquid level of a flowing or agitated liquid, usually a steel pipe with an inner diameter of Φ45mm (a number of small holes are punched at different heights on the opposite side of the liquid flow direction so that the water can enter the pipe smoothly) is fixed in the water, and then the transmitter is placed It can be used in steel pipe.

▲The installation direction of the transmitter is vertical, and the installation position should be far away from the liquid inlet and the agitator.

▲In the use occasions with large vibration, the transmitter can be wound with steel wire, and the steel wire can be used to absorb vibration to avoid breaking the cable.

Precautions For Use

- If an abnormality is found during use, turn off the power supply, stop using it, conduct an inspection or contact the technical department

- When connecting to the power supply, you should strictly follow the wiring instructions for connection.

- The original packaging of the liquid level transmitter should be restored during transportation and storage, and stored in a cool, dry and ventilated warehouse.

![]()

![]()

![]()

| Model Code KSL | Specification | |||||||||

| Type | 1 | Cable Type | ||||||||

| 2 | Rod Type | |||||||||

| Process Connecting | T | Thread | ||||||||

| N | Flange | |||||||||

| Y | Other | |||||||||

| Wetted Material | 1 | NBR (Black color) (standard option) | Cable Type | |||||||

| 2 | Stainless steel cable | |||||||||

| 3 | SS304 | Rod Type | ||||||||

| 4 | SS316 | |||||||||

| Explosion-proof | E | Without Explosion-proof | ||||||||

| F | Explosion-proof Exia ⅡCT6 | |||||||||

| Display | J | Without Display | ||||||||

| K | With Display | |||||||||

| Signal Output | M | 4-20Ma | ||||||||

| W | 1-5V /0-5V/0-10V | |||||||||

| / | Range (mm) | |||||||||

| / | Liquid and Density (g/cm3) | |||||||||