- Have any questions?

- +86 15953537010

- admin@wepower-electronic.com

- Home

- Pressure Measurement

- Pressure Transmitter(WE3051)

- Smart Differential Pressure Transmitter

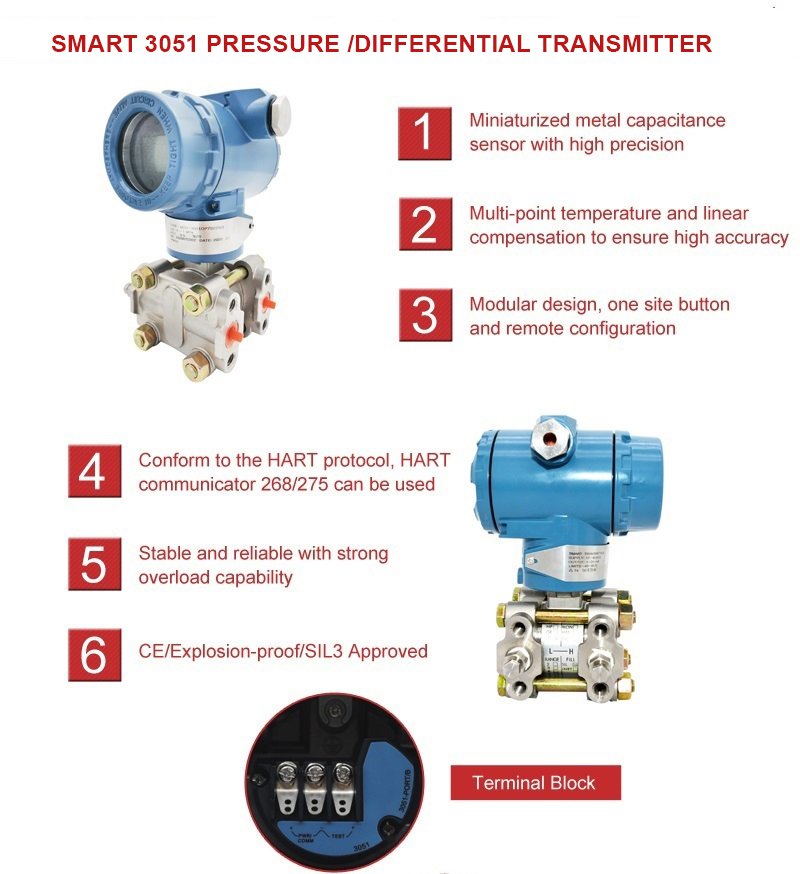

Smart Differential Pressure Transmitter

Smart differential pressure transmitter is used to measure the level, flow and pressure of liquid, gas or steam, convert it into 4-20mA/Hart Protocol signal.Wepower ELectronic WE3051 series differential pressure transmitter adopt the high grade production technology ,very popular with clients both home and abroad.

![]()

Smart Differential Pressure Transmitter is used to measure the level, flow and pressure of liquid, gas or steam, convert it into 4-20mA signal output for PLC or DCS system. Wepower ELectronic WE3051 series differential adopt the high grade technology,produced in the dust-free purification workshop in accordance with high standards of process production and inspection ,very popular with clients both home and abroad many years!

What is the site situation can be measured by Differential Pressure Transmitter ?

- Viscous media at high temperatures

- Medium prone to crystallization

- Sedimentary media with solid particles or suspended matter

- Strongly corrosive or highly toxic media

- Continuously precise measurement of interface and density—The remote transmission device can avoid the mixing of different instantaneous media, so that the measurement results can truly reflect the actual situation of process changes.

- Occasions with high hygiene and cleaning requirements—For example, in the production of food, beverage and pharmaceutical industries, not only the parts of the transmitter that contact the medium are required to comply with hygienic standards, but also should be easy to flush to prevent cross-contamination of different media.

![]()

| Sensor Type | Smart Differential /Pressure Transmitters – |

| Accuracy | ±0.1-0.2% |

| Medium | Liquids, steam and gas |

| Stability | 0.2% |

| Measuring Range | 0~1.5, 0~7.5, 0~37.4, 0~186.8, 0~690, 0~2068 |

| Explosion-proof Type | General type, Exd II C T6 Gb, Exia II C T6 Ga |

| Output Signal | 4-20mA DC, HART |

| Diaphragm Material | SS316L, Hastelloy C, SS316L |

| Diaphragm Fluids | Silicone oil, fluorine oil |

| Drain hole location | Rear face of process flange, Upper side of process flange, Lower side of process flange |

| Process Flange and Bolts | Stainless steel or carbon steel |

| Process flange O-ring material | Buna-N (NBR), Fluorine rubber (FKM) (not below -20 degrees Celsius) |

| Process Connections | NPT1/4 inner bolt |

| Static Pressure | 14Mpa (range2 =4Mpa; range3=7Mpa) /25Mpa/32Mpa |

| Power Supply | 9-32 V DC |

| Bracket | None, Tube mounted bend bracket (carbon steel), Wall mounted bracket (carbon steel), Tube mounted flat bracket (stainless steel), Wall mounted bracket (stainless steel), Tube mounted flat bracket (stainless steel) |

![]()

![]()

![]()

![]()

![]()

| Name | Specification code | Description | ||

| WE3051GP WE3051DP |

/ | Pressure Transmitter Differential Pressure Transmitter |

||

| / | 3 | (0.013-0.075)bar | ||

| 4 | (0.062-0.374)bar | |||

| 5 | (0.31-1.868)bar | |||

| 6 | (1.17-6.9)bar | |||

| 7 | (3.45-20.68)bar | |||

| 8 | (11.7-68.90)bar | |||

| 9 | (34.8-206.8)bar | |||

| 0 | (68.9-413.7)bar | |||

| Output Signal | E | analog type 4-20mA | ||

| S | 4-20mA, HART Protocol Digital Communication | |||

| Wetted Parts Material |

/ | Flange/Joint | Exhaust/Drain Valve | Diaphragm |

| 22 | Stainless Steel | Stainless Steel | 316L Stainless Steel | |

| 23 | Hastelloy C-276 | |||

| 24 | Tantalum | |||

| Mounting Bracket |

B1 | Tube-type Curved Bracket (Tube ODΦ50~Φ60) | ||

| B2 | Board- type Curved Bracket | |||

| B3 | Tube-type Straight Bracket (Tube ODΦ50~Φ60) | |||

| Display Header (optional) |

M2 | Linear Pointer Header (0~100% scale) | ||

| M3 | Square Root Instruction Header(0~100% scale) | |||

| M4 | LCD Header(0~100% linear display) | |||

| Process Flange | D | The liquid discharge / exhaust at the back | ||

| D1 | The liquid discharge / exhaust at the side top | |||

| D2 | The liquid discharge / exhaust at the side bottom | |||

| Flange Joint | J | “D-shaped” Joint with ” M20*1.5″ External thread | ||

| / | N | Joint with 1/2-14NPT taper pipe thread waist type | ||

Wepower Electronic is constantly in the lead for the greatest quality and service ! Contact us now!