- Have any questions?

- +86 15953537010

- admin@wepower-electronic.com

- Home

- Flow Meter

- Oval Gear Flow Meter

- Rotary Positive Displacement Meter

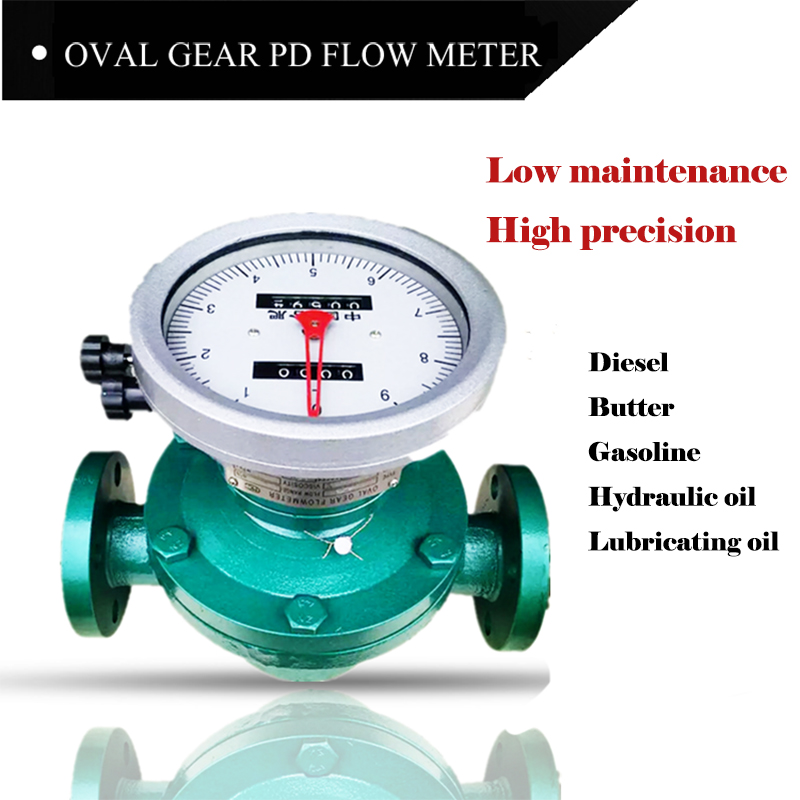

Rotary Positive Displacement Meter

Rotary positive displacement meter is an automated PD flow meter with gears inside. The biggest feature of Rotary positive displacement meter is energy saving and low maintenance cost. The Rotary positive displacement meter is unaffected by fluid flow state and has a wide measurement range, making it popular for measuring special liquids in some industrial fields.

![]()

Bioadhesives like animal glue, natural rubber, etc. are measured with a rotary positive displacement meter( oval gear flowmeter). It is extensively employed in the manufacturing of cosmetics. It should be mentioned that frequent testing and verification of the Rotary positive displacement meter is necessary to obtain better measurement results. It is preferable to test a rotary positive displacement meter without water if it is made of cast iron or cast steel. We advise consumers to experiment with lubricating oil.

According to the differnet output ,how to classify rotary positive displacement meter ?

Three types of rotary positive displacement meters are often distinguished: those with an LCD display, those with a 4-20mA output, and those that are mechanical pointer rotary positive displacement meters.

The mechanical pointer type and pulse output type rotary positive displacement meters can only show the accumulated flow, in contrast to the rotary positive displacement meter with LCD. A rotary positive displacement meter with a zero return handle is the mechanical form of pointer. There is no need to charge the mechanical pointer kind. Only pulses can be output by the rotating positive displacement meter with pulse output, and neither the pointer type nor the pulse output type can output currents between 4 and 20 mA. The LCD-equipped rotary positive displacement meter can provide immediate and cumulative flow, pulse, 4–20 mA, and RS485 as optional features.

When choosing the model style, users can configure the explosion-proof dial according to their own needs. Explosion proof rotary positive displacement instruments can withstand extreme pressure and temperature. High temperature type and explosion-proof type can also be used in combination

![]()

![]()

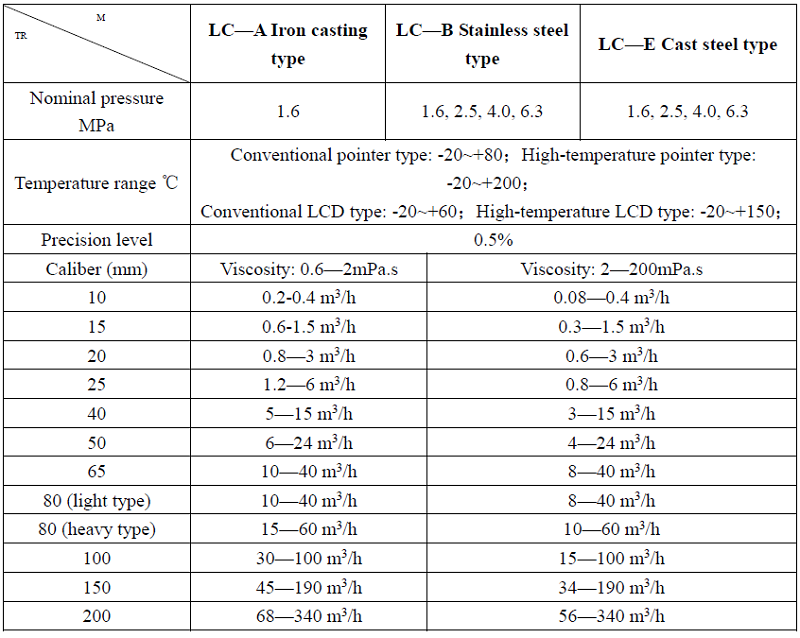

1)Oval gear flowmeter of iron casting type, cast steel type and stainless steel type:

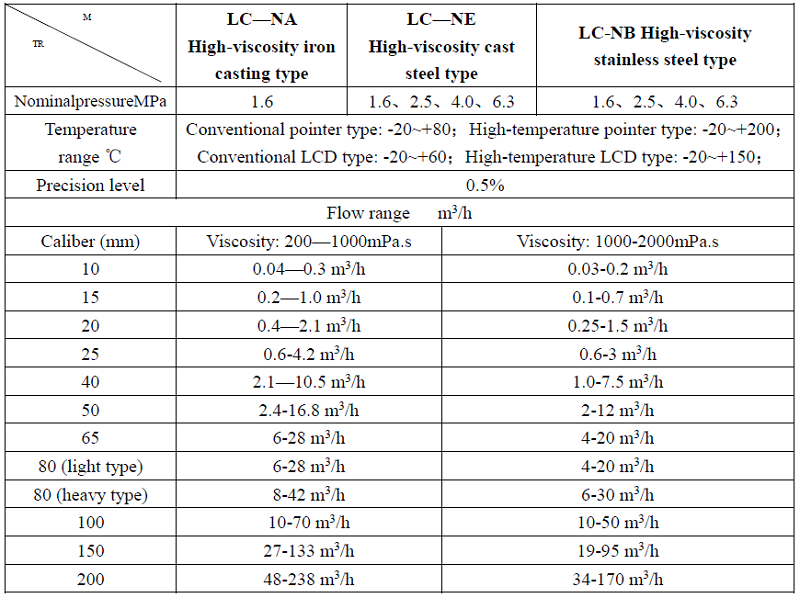

2)Oval gear flowmeter of high viscosity type:

![]()

1.A matching filter shall be installed before the oval gear flowmeter, and the outlet of the matching filter is

connected to the inlet of the flowmeter. The arrow points on both bodies are consistent with the

flow direction of the liquid.

2. When the liquid umder test contains gas, the gas elimination filter should be installed before the

Flowmeter.

3.No matter whether the pipeline is installed vertically or horizontally, the oval gear in the flowmetel

shall be installed in a horizontal position (i.e. the gauge disc shall be perpendicular to the ground).

4. When the flowmeter is properly installed, if it is not easy to read, turn the counter to 180 degrees or

90 degrees.

5. The new flowmeter pushes the elliptical gear several times fiom the exit with a bamboo stick before

installation. If it doesn’t move, soak in diesel oil (Avoid sediment after factory check).

6. Flow control valve should be installed at the inlet of the Flowmeter, and open and close valve is

installed at the outlet. When using open and close valve, start slowly, do not suddenly open to

prevent “water hamer” phenomenon.

7. Before installing the flowmeter on the new pipeline, the pipeline needs to be flushed, and the straight

pipe section (instead of the position of the Flowmeter) is used to prevent welding slag, sundries and

so on from entering the flowmeter.

8. It is strictly forbidden to check the flowmeter of cast iron and steel with water.

9.The flow size of the flowmeter in use shall not exceed the technical requirements. The flowmeter

operates at a maximum flow rate of 50-80%

10.If the tested liguid is chemically corrosive, a flowmeter of stainless steel should be selected

![]()