- Have any questions?

- +86 15953537010

- admin@wepower-electronic.com

- Home

- Level Meter

- Radar Level Transmitter

- 26G Radar Level Meter

- Radar Level Transmitter For Corrosive Liquid

Radar Level Transmitter For Corrosive Liquid

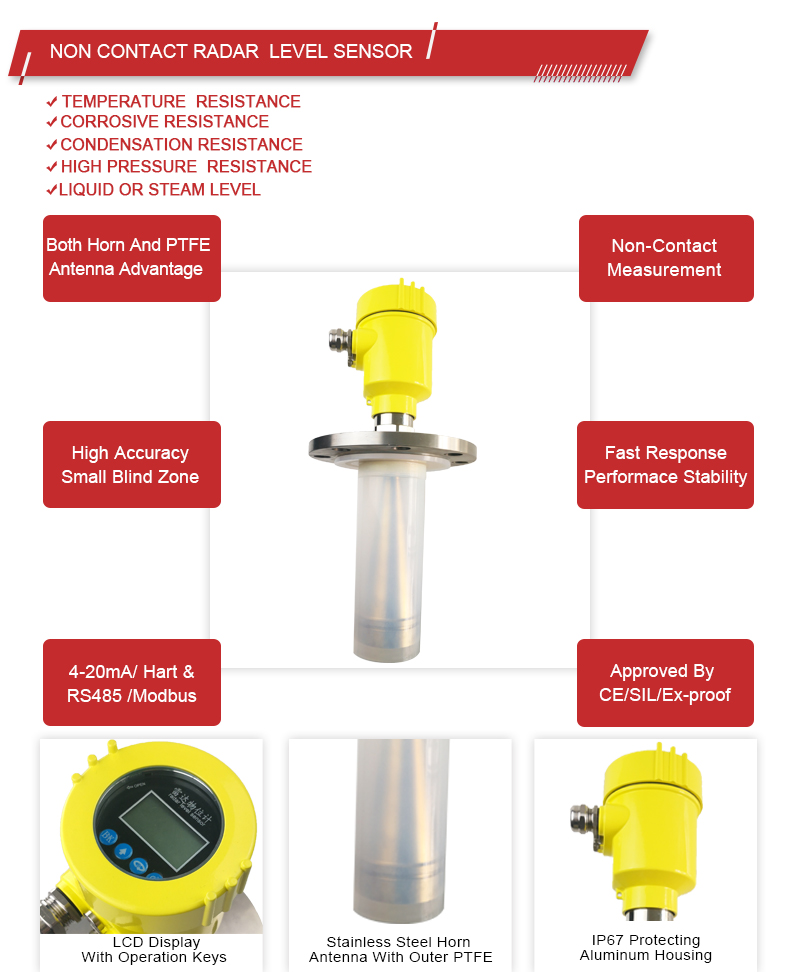

WERD807 Radar Level Transmitter is designed for measuring corrosive liquids, corrosive vapors ,volatile liquids; also can prevent condensation during measurement .

![]()

There are two types of Radar Level Transmitters: contact type and non-contact type. The non-contact type radar level transmitter is comparatively hygienic and safe, making it appropriate for environments with high levels of health and safety as well as strong corrosiveness. Measurement without touch, integrated design, no detachable parts, safe and practical The potent microprocessor enables real-time measuring and executes numerous intricate calculations. Due to its exceptional sensitivity and special signal processing capabilities, it can operate in storage tanks with challenging measurement conditions. For severe corrosive liquid vapor, high-temperature condensation, etc.

The purpose of the WERD807 Radar Level Transmitter is to monitor volatile liquids, corrosive vapors, and corrosive liquids. It may also stop condensation while measuring. Our RD807 is a more practical and efficient solution for situations involving high temperatures, strong corrosive liquid vapor, etc. It has been widely acknowledged by customers.

![]()

| Product Name | 26G Radar type level transmitter |

| Model | RD807 |

| Medium | Corrosive liquid |

| Process Connection | Thread G1½″A ,Thread 1½ ,NPT, Universal Flange |

| Measurement Accuracy |

± 5mm |

| Display | LCD, Programmable |

| Material |

Antenna :PTFE |

| The seal between the shell and the shell cover: Silicone rubber | |

| Casing window: Polycarbonate | |

| The ground terminal: Stainless Steel | |

| Housing : Aluminum / Stainless steel | |

| Cable parameters | Cable entrance / plug: 1 M20xl.5 cable entrance ;1 blind plug |

| Terminal : Conductor cross section 2.5mm² | |

| Power Supply: | 2-wire(DC24V)/ 4-wire(DC24V /AC220V ) |

| Output signal | 4… 20mA / HART (2-wire / 4-wire ) |

| RS485/ Modbus | |

| Blind area | the ends of the antenna |

| Maximum measuring range | 30 |

| Pressure | -0.1-4MPa |

| Adjust time | about 1 second (depending on the parameter settings) |

| Explosion-proof Grade | ExiaⅡC T6 Ga / Exd ⅡC T6 Gb |

| Process temperature | -40℃~130℃ the temperature of the antenna part |

| Working & Storage Temperature | (-40~100) ℃ |

![]()

![]()

Explosion Proof Connection

The intrinsic safety version sensors (Exia IIc T6) use Alu-die casting housing and filling Silicone rubber sealants internal structure aimed to prevent sparks resulted from circuit failure from leaking out. It is applicable for the continuous level measurement of flammable medium under Exia IIc T6.

A safety barrier FBS-2 must be used together with the intrinsic safety instrument. It is an associated device to this product for the power supply of this product. The main specification is intrinsic safety: Exia IIC, voltage of power supply: 24V DC±5%, short-circuit current: 135mA, operating current: 4…20mA.

All cables must be shielded. The max length is 500m for the cable from the barrier to the sensor. Stray capacitor≤0.1μF/Km, stray inductance 1mH/Km. Instrument must be connected to the ground potential. Any unapproved associated device is not allowed to be used.

Instruments Commissioning

There are three kinds of debugging method:

1) Display / Keyboard

2) Host debugging

3) HART handheld programmer

● Display / Keyboard

Please debug the instrumentation by four buttons on the display screen. There are three debug menu languages optional. After debugging is generally used only for display, through the glass window can read measured value very clearly.

| Display / Keyboard① Liquid crystal display(LCD)

② The key |

|

| ● PC debugging:Connected to PC by HART

①RS232 interface or USB interface ②Radar level meter ③HART adapter ④250 Ω resistor |

|

| ● HART handheld programmer:① HART handheld programmer

② Radar level meter 250 Ωresistor |

|

![]()