- Have any questions?

- +86 15953537010

- admin@wepower-electronic.com

- Home

- Pressure Measurement

- Pressure Transmitter(WE3051)

- Pressure Differential Transmitter

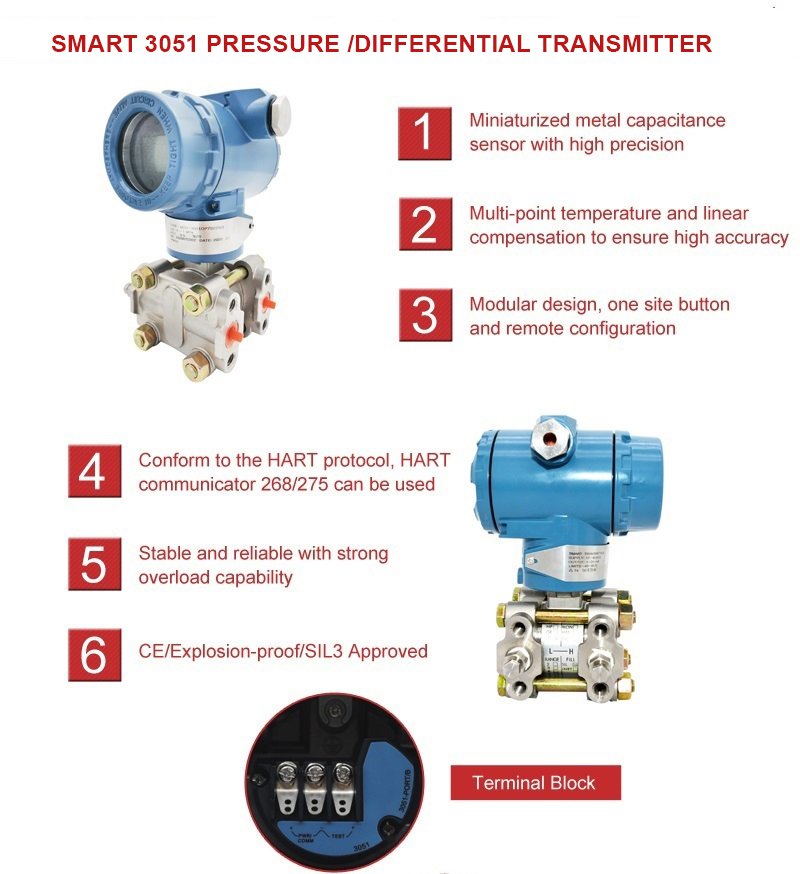

Pressure Differential Transmitter

Differential pressure transmitters are generally divided into high-pressure ends(H) and low-pressure ends(L). Generally, the pressure at the high-pressure end of a differential pressure transmitter should be greater than the pressure at the low-pressure end before measurement can be made.

![]()

Pressure Differential Transmitters are different from ordinary pressure transmitters in that they have two pressure interfaces. Differential pressure transmitters( DPT) are generally divided into high-pressure ends(H) and low-pressure ends(L). Generally, the pressure at the high-pressure end of a differential pressure transmitter should be greater than the pressure at the low-pressure end before measurement can be made.

There are 2 serial core capacitors and an anti-interference circuit board inside the transmitter to prevent pulse interference and surges. Our self-developed differential pressure measuring transmitter updates the electronic components made of monocrystalline silicon and utilizes the piezoresistive effect of monocrystalline silicon, which results in higher range accuracy, stronger stability, and longer usability.

![]()

| Sensor Type | Smart Differential Pressure Transmitters |

| Accuracy | ±0.1-0.2% |

| Medium | Liquids, steam and gas |

| Stability | 0.2% |

| Measuring Range | 0~1.5, 0~7.5, 0~37.4, 0~186.8, 0~690, 0~2068 |

| Explosion-proof Type | General type, Exd II C T6 Gb, Exia II C T6 Ga |

| Output Signal | 4-20mA DC, HART |

| Diaphragm Material | SS316L, Hastelloy C, SS316L |

| Diaphragm Fluids | Silicone oil, fluorine oil |

| Drain hole location | Rear face of process flange, Upper side of process flange, Lower side of process flange |

| Process Flange and Bolts | Stainless steel or carbon steel |

| Process flange O-ring material | Buna-N (NBR), Fluorine rubber (FKM) (not below -20 degrees Celsius) |

| Process Connections | NPT1/4 inner bolt |

| Static Pressure | 14Mpa (range2 =4Mpa; range3=7Mpa) /25Mpa/32Mpa |

| Power Supply | 9-32 V DC |

| Bracket | None, Tube mounted bend bracket (carbon steel), Wall mounted bracket (carbon steel), Tube mounted flat bracket (stainless steel), Wall mounted bracket (stainless steel), Tube mounted flat bracket (stainless steel) |

![]()

![]()

![]()

![]()

![]()

| Name | Specification code | Description | ||

| WE3051GP WE3051DP |

/ | Pressure Transmitter Differential Pressure Transmitter |

||

| / | 3 | (0.013-0.075)bar | ||

| 4 | (0.062-0.374)bar | |||

| 5 | (0.31-1.868)bar | |||

| 6 | (1.17-6.9)bar | |||

| 7 | (3.45-20.68)bar | |||

| 8 | (11.7-68.90)bar | |||

| 9 | (34.8-206.8)bar | |||

| 0 | (68.9-413.7)bar | |||

| Output Signal | E | analog type 4-20mA | ||

| S | 4-20mA, HART Protocol Digital Communication | |||

| Wetted Parts Material |

/ | Flange/Joint | Exhaust/Drain Valve | Diaphragm |

| 22 | Stainless Steel | Stainless Steel | 316L Stainless Steel | |

| 23 | Hastelloy C-276 | |||

| 24 | Tantalum | |||

| Mounting Bracket |

B1 | Tube-type Curved Bracket (Tube ODΦ50~Φ60) | ||

| B2 | Board- type Curved Bracket | |||

| B3 | Tube-type Straight Bracket (Tube ODΦ50~Φ60) | |||

| Display Header (optional) |

M2 | Linear Pointer Header (0~100% scale) | ||

| M3 | Square Root Instruction Header(0~100% scale) | |||

| M4 | LCD Header(0~100% linear display) | |||

| Process Flange | D | The liquid discharge / exhaust at the back | ||

| D1 | The liquid discharge / exhaust at the side top | |||

| D2 | The liquid discharge / exhaust at the side bottom | |||

| Flange Joint | J | “D-shaped” Joint with ” M20*1.5″ External thread | ||

| / | N | Joint with 1/2-14NPT taper pipe thread waist type | ||

Wepower Electronic is constantly in the lead for the greatest quality and service ! Contact us now!