- Have any questions?

- +86 15953537010

- admin@wepower-electronic.com

- Home

- Density Meter& Viscosity Meter

- Vibration Fork Density Meter

- Oil Density Meter

Oil Density Meter

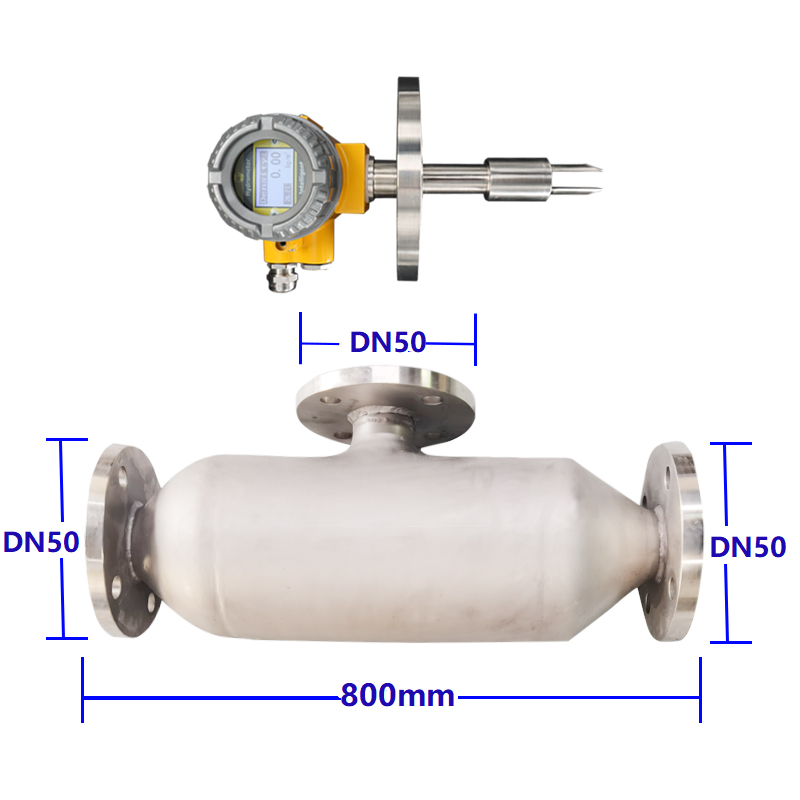

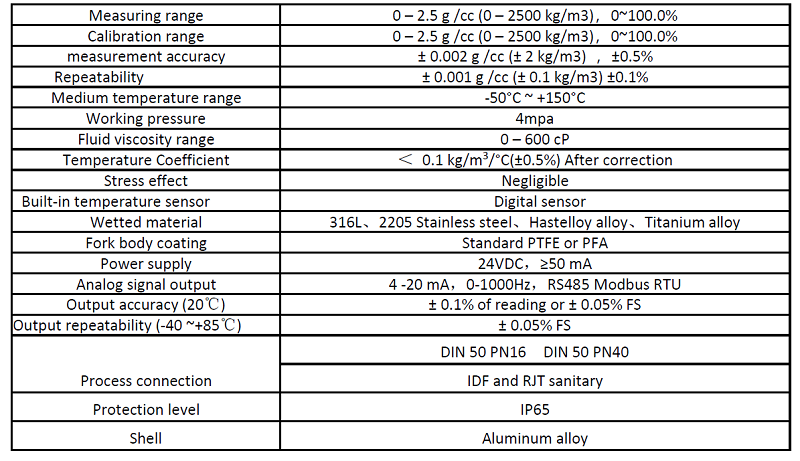

WPX301 oil density meter is a multi-functional and flexible precision measuring instrument designed by vibronic fork principle. The shell of the online oil density meter is made of aluminum alloy, which has good explosion-proof performance. A temperature sensor is installed inside the digital online oil densitometer for temperature compensation which can be used to reduce the influence of temperature on the measuring medium.

![]()

The vibronic fork technique was used to create the versatile and multipurpose WPX301 oil density meter. The online oil density meter’s shell is composed of an aluminum alloy, which performs well in terms of explosion resistance. To lessen the impact of temperature on the measurement medium, a temperature sensor is incorporated into the digital online oil densitometer for temperature compensation.WPX301 tuning fork oil density meters are commonly used, particularly in the chemical, lubricating, and fuel processing sectors, and can be installed directly on tanks, pipelines, and passby loops.

![]()

Does the flow rate have any effect on the WPX301 oil density meter?

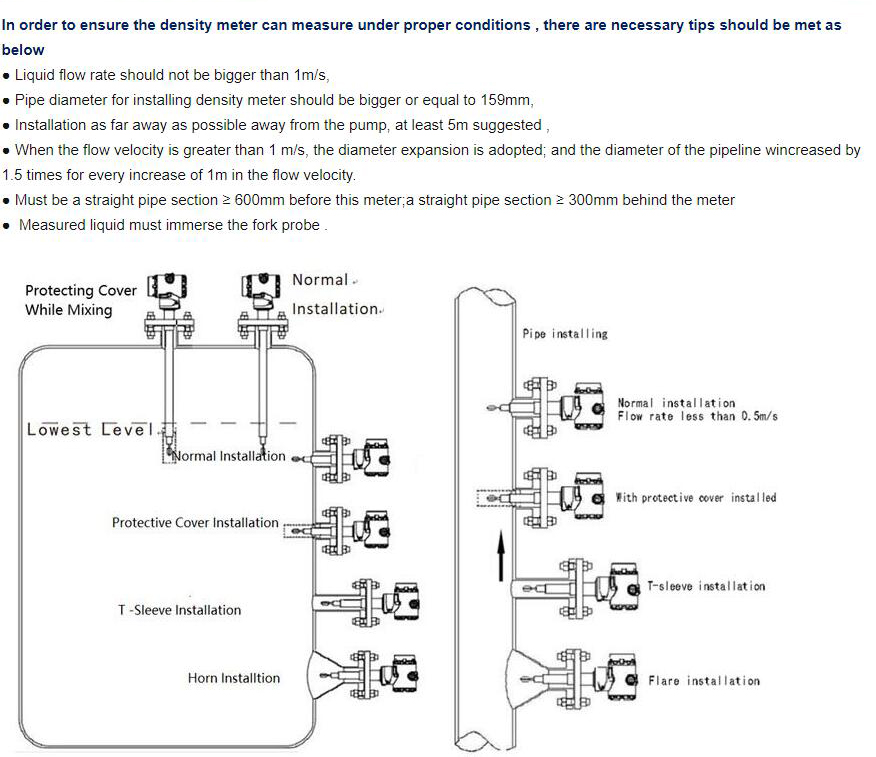

The flow rate has an impact on the WPX301 oil density meter, so the user should confirm the conditions such as the flow rate in the measuring pipe and the measuring pipe diameter before installation.

The user must install the diameter expansion when the flow rate exceeds 1 m/s. The diameter of the pipeline where the density meter is mounted increases by 1.5 times for every 1m increase in flow rate. At the outflow end of the oil density meter, there must be at least a 300mm straight pipe section for the pipe section. This procedure makes that the fluid is moving through the fork in a “laminar state.”

![]()

![]()

Which points you should learn for installation oil fork density meter correctly?

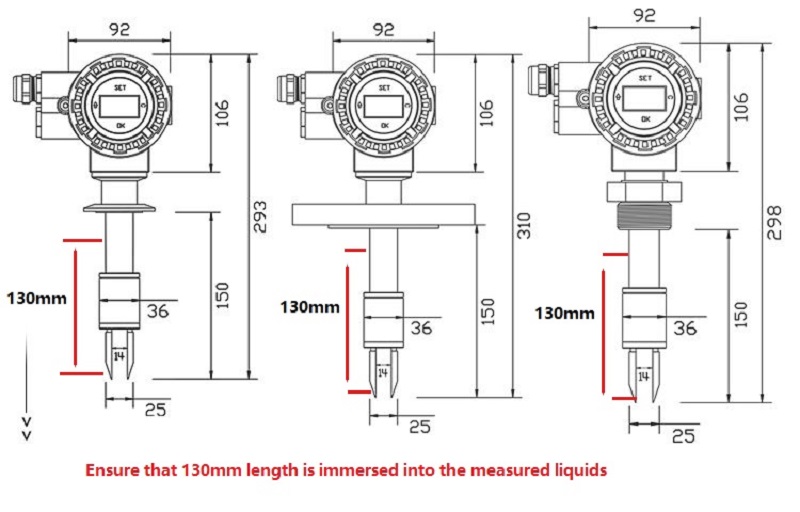

Density meters can be installed on sealed tanks in a number of ways. Standard installation techniques, protective cover installation techniques, T-sleeve installation techniques, and flare installation techniques are all available. Within the spectrum of possible normal functioning, users can do self-installation in accordance with their particular working conditions.

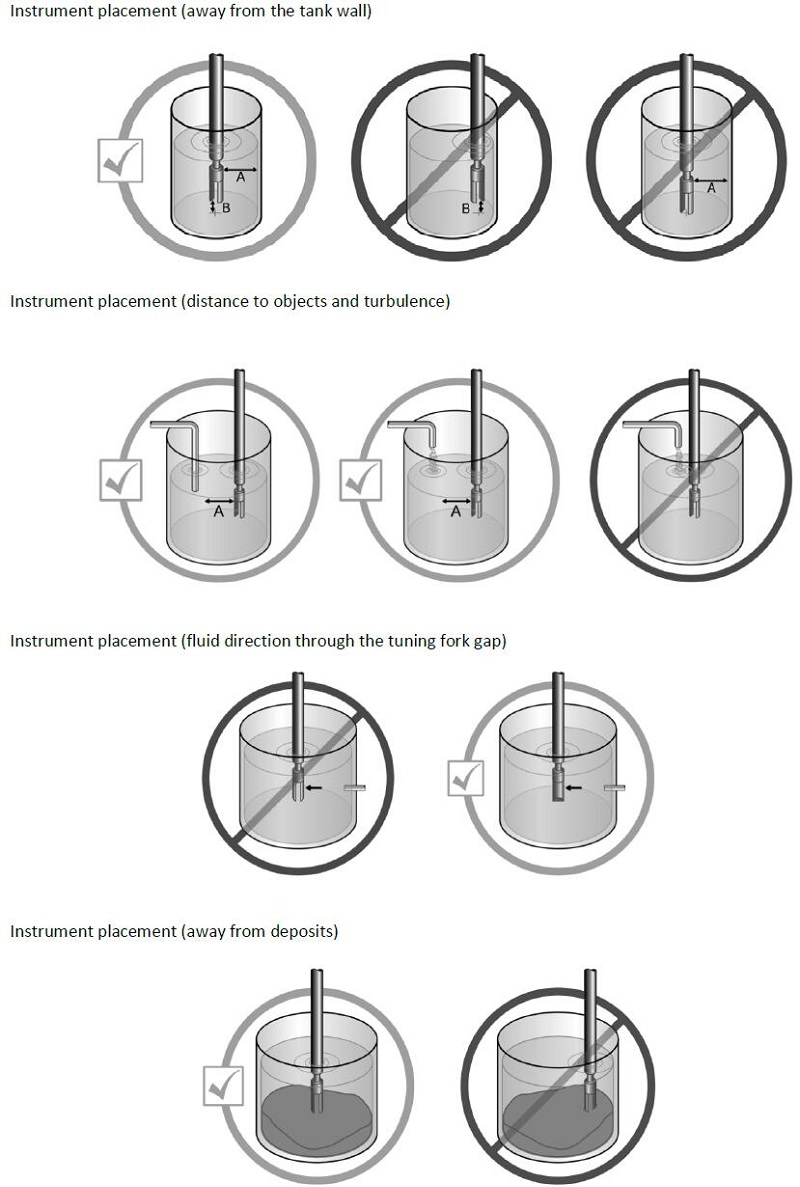

1. It is not recommended that the liquid density meter be installed too near the inlet valve.

2. It is incorrect that during the measurement, the tuning fork portion of the WPX301 water fluid density meter was not completely “immersed” in the liquid surface.

3. It is not advised to install the water density meter very near the pipe’s bend.

![]()

![]()

For learn more about our WPX301 Densitometer , please click photo below to our youtube video list :