- Have any questions?

- +86 15953537010

- admin@wepower-electronic.com

- Home

- Density Meter& Viscosity Meter

- Tuning Fork Viscosity Meter

- Micro Motion Viscosity Meter

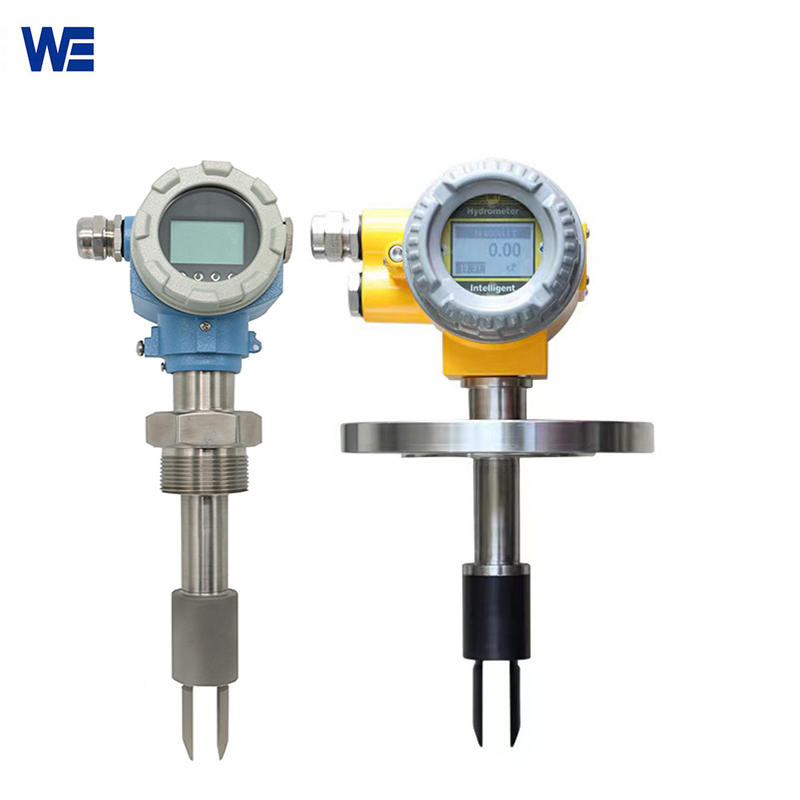

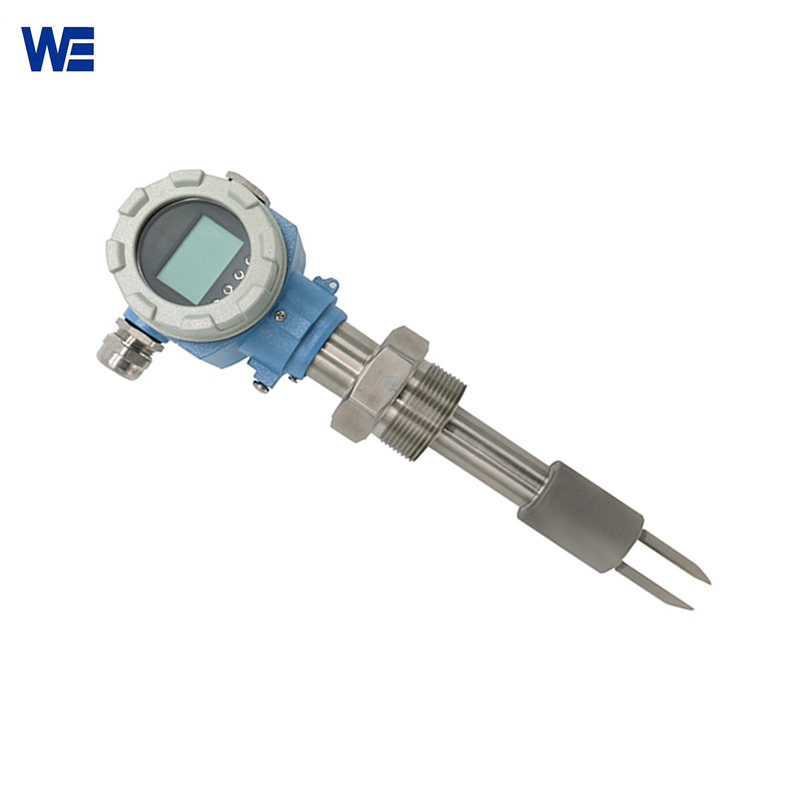

Micro Motion Viscosity Meter

Micro Motion Viscosity Meter (FVM) uses a direct insertion tuning fork design to provide precise, measurements of viscosity and density. WEpower is the industry pioneer who is alway here for the one -stop solution for online real time viscosity /density measurement and control, online fork viscometer is widely used and smart choice for many industries.

![]()

The Micro Motion Viscosity Meter (FVM) provides accurate online viscosity and density measurements through the direct insertion tuning fork design.

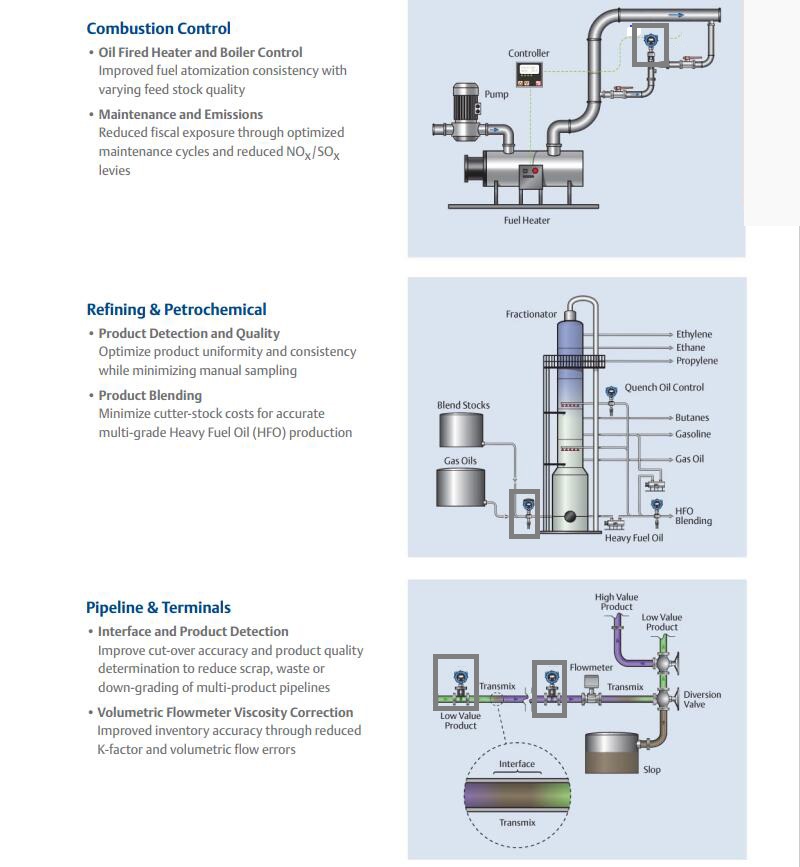

The final product quality, blending procedures, and efficient combustion of various process liquids, such as lubricants, asphalts, and refined products, are all enhanced by the WPX401 online Micro Motion Viscosity Meter. Additionally, it enhances the standard for density and viscosity monitoring inline. Installing a tee to join the pipes is advised when installing on pipes if the pipe size is too small. Additionally, there are two mounting options for the micro motion viscosity meter: side and top. Customers all around the world appreciate our cutting-edge WPX401 online fork viscometer products because of their excellent cost-performance ratio.

![]()

| Product | Micro Motion Viscosity Meter |

| Viscosity Measuring Range | 0-20,000cP |

| Viscosity Accuracy | ±0.2cP (0-10cP) then ±1%

Full scale of calibrated range max ±1cP (10-100cP), ±10cP (100-1000cP), ±125cP (1000-12,500cP) |

| Temperature Accuracy | BS1904, DIN 43760 Class ‘B’ (±0.30 ±0.005 X T)°C |

| Wetted material | SS316;PTFE;PFA; tantalum; Hastelloy C |

| Housing Material | Die-casting aluminum/ Stainless Steel |

| Safety Approvals | Explosion/Flame-Proof |

| Process Connecting : | Flange, thread, tri-clamp |

| Display | Two-line, LCD screen

Optical switch configuration |

| Outputs | Standard: 4-20mA, HART, Modbus RS-485 |

| Protection Class | Ingress Protection: IP66/67 |

| Dimensions | 355 mm (h) x 163 mm (w) x 163 mm (d) (Typical short stem version) |

| Weight (Typical) | 6.7 kg (15 lbs) |

![]()

![]()

![]()