- Have any questions?

- +86 15953537010

- admin@wepower-electronic.com

- Home

- Density Meter& Viscosity Meter

- Vibration Fork Density Meter

- Micro Motion Liquid Density Meter

Micro Motion Liquid Density Meter

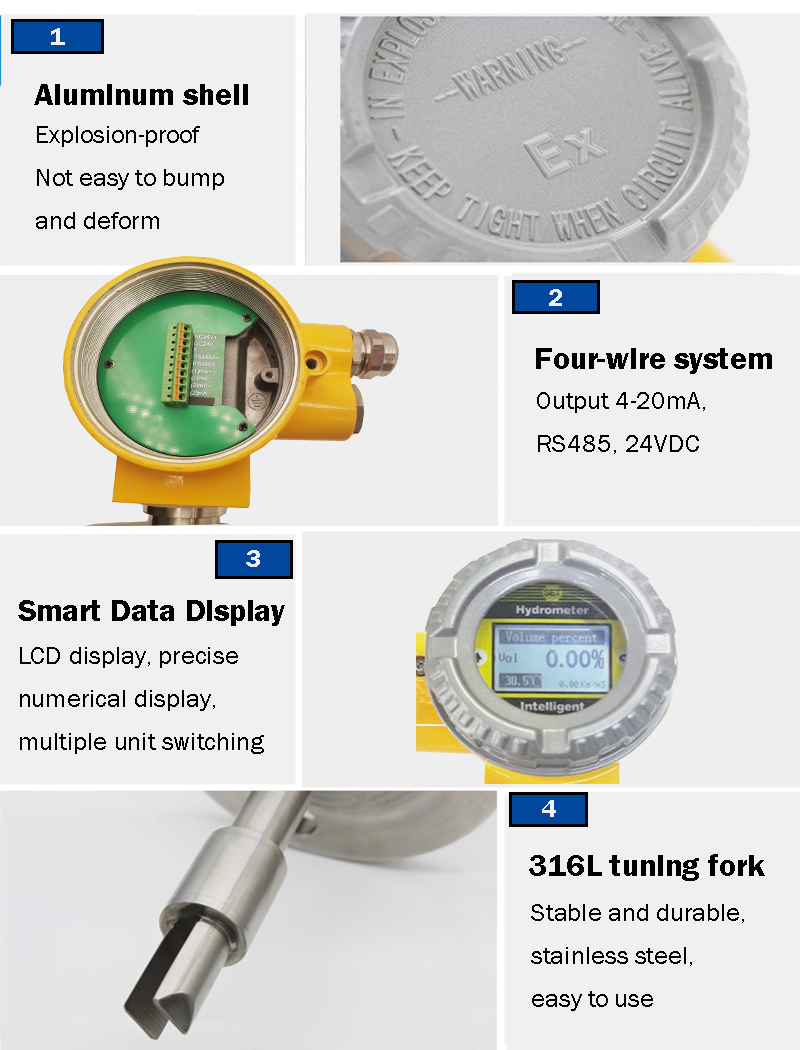

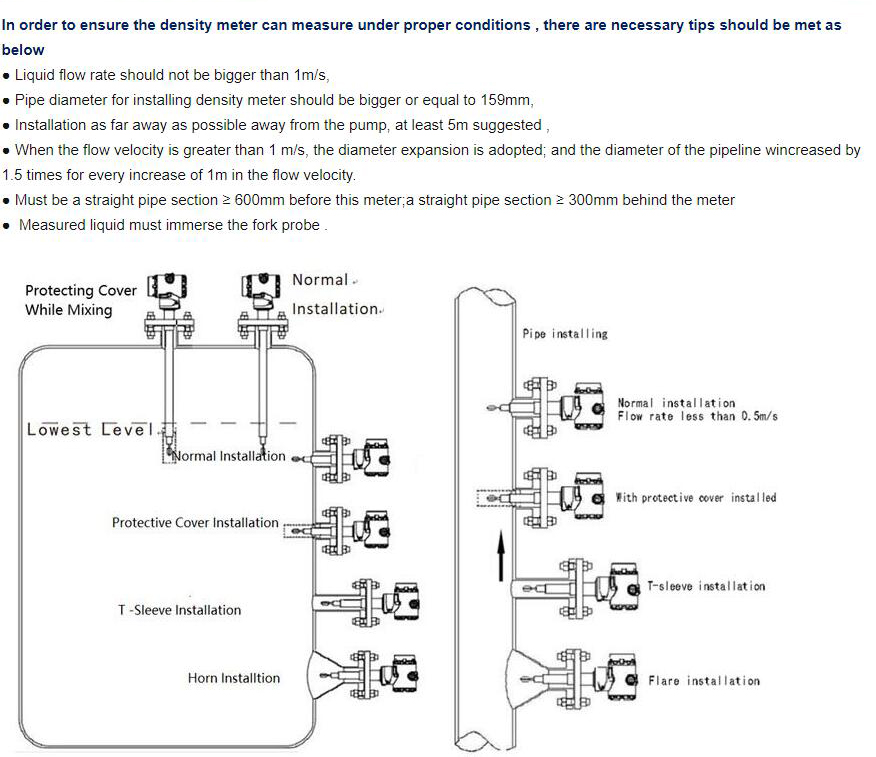

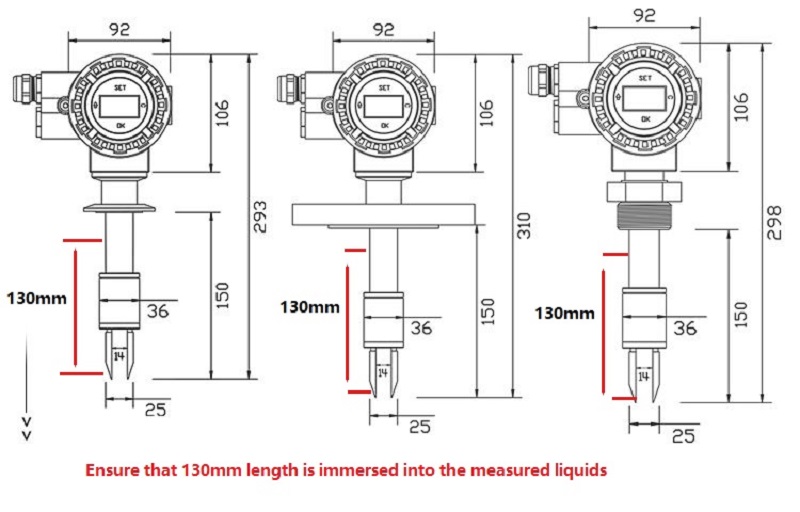

Micro Motion Liquid Density Meter is widely used in pipelines, passby loops ,open tanks, or closed tanks to detect the density &concentrationof the liquids medium . The density of the fluid directly depends on the vibration frequency received by the tuning fork in the sensor which inserted into the medium, this advanced continuous and real time measurement make WPX301 more and more popular density instrument in various industries .

![]()

Micro Motion Liquid Density Meter is widely used in pipelines, passby loops ,open tanks, or closed tanks to detect the density / concentrationof the medium . The density of the fluid directly depends on the vibration frequency received by the tuning fork in the sensor which inserted into the medium. It is continuous, real-time measurement in pipelines, bypass loops, and tanks. The built-in temperature sensor provides temperature compensation . The liquid medium temperature can be displayed on the displaying screen of the denisty meter too .

WPX301 micro motion density meter by Wepower Electronic is insensitive to vibration, temperature, and pressure variations, which ensure the stable measuring and high accuracy ,accurate measurement of density can reach (±1 kg/m3) and concentration (up to ±0.1%) , which is more and more popular density instrument in various industries .

![]()

![]()

| Product name | Tuning Fork Densitometer/Density Meter Online For Liquids / Mico Motion Liquid Density Meter |

| Measurement range | 0-2.5 g /cc (0-2500 kg/m3);,0~100.0% |

| Medium | Liquid;slurry , liquid mixture |

| Function | Test Density and Concentration online |

| Temperature range | -50 c ~+150 c |

| Accuracy | ±1-2kg/m3(± 0.002 g/cc ) |

| Max Working Pressure | 207bar (3000psi) |

| Medium Viscosity | 0-10000cp;Fluid viscosity range 0-2000cp |

| Power Supply | 24 V DC |

| Signal Output | 4 -20 mA,0-1000Hz,RS485 Modbus RTU |

| IP Grade | IP67 |

| Wetted Material | SS316/SS2205/Hastelloy C/ PTFE |

| Process Connecting | Flange (ANSI 150 ~1500 RF,DIN 50 PN16,DIN 50 PN40) /Tri- clamp /Thread |

| Disadvantage | not ideal for measuring crystallization and fouling media |

![]()

![]()

![]()

![]()

| Ordering Sheet | |||||||

| WPX301 | Vibrating Densitometer | ||||||

| / | CODE | Type | |||||

| A | Common | ||||||

| B | High Temp | ||||||

| C | Hygeian(Sanitary) | ||||||

| / | CODE | Length | |||||

| 01 | 150mm(Standard) | ||||||

| 02 | 200mm(Standard ) | ||||||

| 03 | Rod Extension 150mm~3000mm | ||||||

| / | CODE | Pressure | |||||

| D | 24V DC±10% | ||||||

| / | CODE | Material | |||||

| 1 | 316(Standard ) | ||||||

| 2 | 2205 | ||||||

| 3 | Hastelloy C | ||||||

| 4 | Anti-corrosive ,with coated PTFE | ||||||

| 5 | Other Customer Request | ||||||

| / | CODE | Process Connecting | |||||

| G | Dn50 PN16 316L | ||||||

| T | 1.5”G Thread | ||||||

| C | Tri-Clamp | ||||||

| F | Other Customer Request | ||||||

| / | CODE | Other Parameters | |||||

| A | Normal Temperature ℃ | ||||||

| B | Normal Pressure Kpa | ||||||

| C | IP Grade :IP67 | ||||||

| D | Explosion-proof :ExdⅡ CT5 | ||||||

| E | Temp:℃ | ||||||

| F | Pressure : Kpa or Mpa | ||||||

| () | Other Customer Request | ||||||

| WPX301 | A | 01 | D | 1 | G | AB (Example ) | |

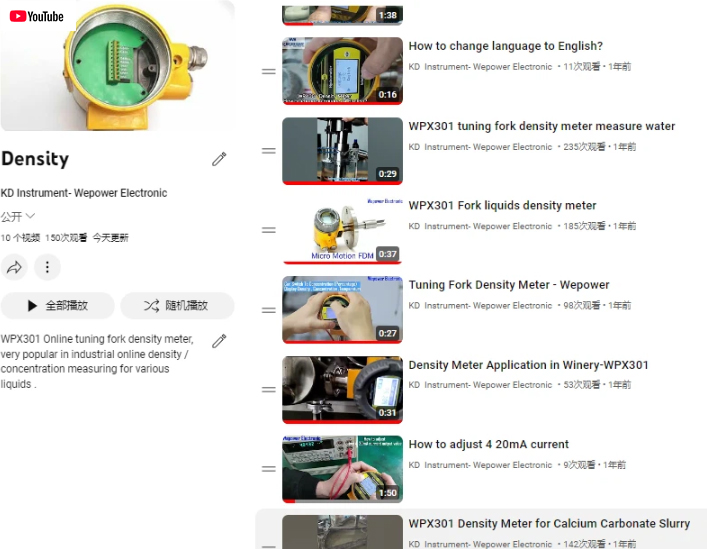

For learn more about our WPX301 Densitometer , please click photo below to our youtube video list :