- Have any questions?

- +86 15953537010

- admin@wepower-electronic.com

- Home

- Level Meter

- Magnetostrictive Level Meter

- Magnetostrictive Level Transmitter For Tank

Magnetostrictive Level Transmitter For Tank

Magnetostrictive Level Transmitter has the characteristics of high precision, good stability and fast response, and is widely used in fields such as industry, petrochemical industry, environmental protection, medicine and food, shipbuilding and marine engineering, and energy.

![]()

What Industries Can Magnetostrictive Level Transmitter For Tank Be Used?

▲Liquid Level Measuring On Industrial Production Lines

In industrial production lines, magnetostrictive level transmitter for tank can be used to monitor the liquid levels of various liquid containers, such as storage tanks, reactors, boilers, etc.

▲Liquid Level Measurement In Petrochemical Industry

In the petrochemical industry, there are many types of liquid materials, and most of them are corrosive, high temperature and high pressure. The magnetostrictive level transmitter can work stably in harsh working environments and accurately measure liquid level.

▲Environmental Protection And Sewage Treatment Fields

Real-time monitoring of liquid levels in sewage treatment tanks, sedimentation tanks and other equipment can ensure the smooth progress of the sewage treatment process.

▲Level Control In The Pharmaceutical And Food Industries

In the pharmaceutical and food industries, the requirements for liquid level control are very high. Magnetostrictive level transmitter are widely used in liquid level control of pharmaceutical storage tanks, fermentation tanks, reactors and other equipment due to their high measurement accuracy and good stability. Through precise control of liquid level, product quality and stability of the production process can be ensured.

▲Liquid Level Monitoring In Ships And Offshore Engineering

In shipbuilding and marine engineering, magnetostrictive level transmitter for tank can be used to monitor the liquid level of equipment such as cabins and fuel tanks. Since ships will be affected by external factors such as wind and waves during navigation, the measurement and control of liquid level is particularly important.

![]()

| Product | Magnetostrictive level transmitter for tank (WPX 901) |

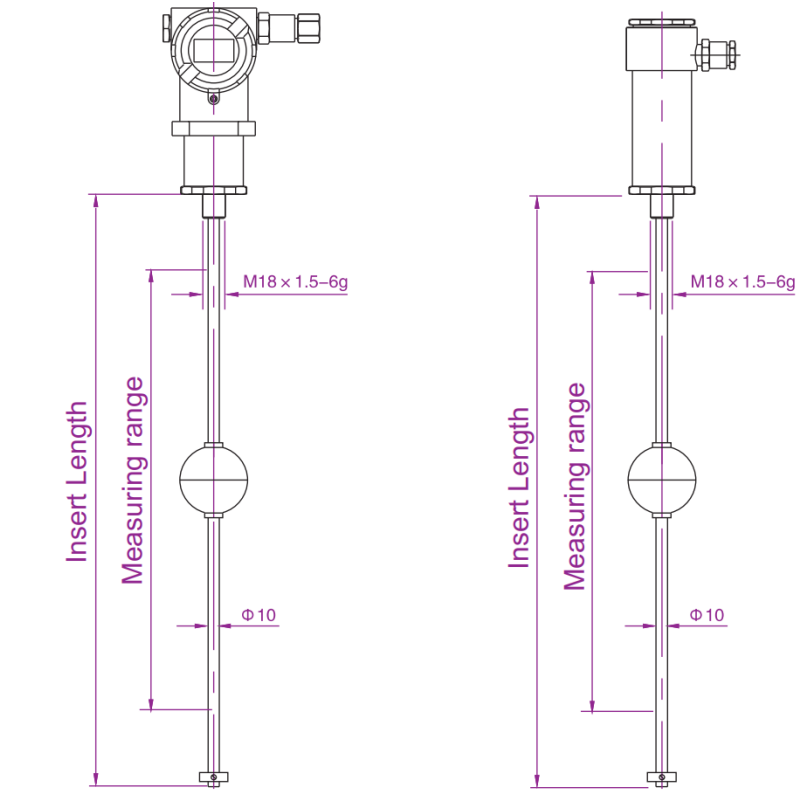

| Measuring range | 100-5000mm |

| Wetted material | AISI304, AISI316, PTFE etc. |

| Measurement field | Water, aqueous solution, beverages, food production, beverage production, chemical reagent production, petrochemical industry, crude oil storage, etc. |

| Medium | specific gravity ≥0.5g/cm3 and viscosity 1.25St |

| Accuracy | :≤±0.1%FS or 1um, whichever is the maximum |

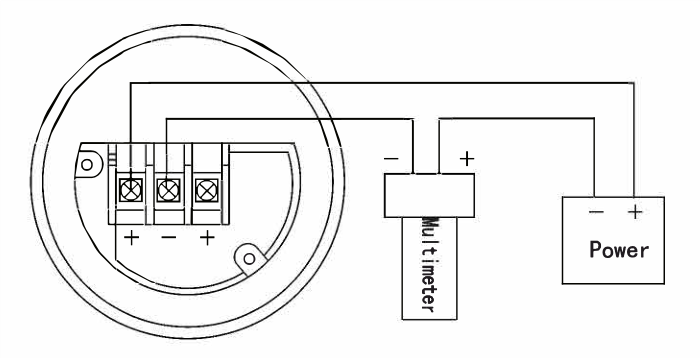

| Power supply | DC12-36V |

| Output | two-wire 4-20mA+HART (optional) |

| Measurement display resolution | 0.3mm |

| Nonlinearity | <±0.05%FS |

| Hysteresis | ≤±0.002%FS |

| Temperature | -40-85°C (special instruction are required if it exceeds 85°C) |

| Pressure | 0-1Mpa (special indication is required when exceeding 1Mpa) |

| Explosion-proof | EXiaⅡCT4 intrinsically safe type |

| Junction box protection level | IP65 |

| Magnetic float ball | Standard ø76 special supply ø48, ø51, ø120,

ø145 or user’s choice. Float height F: ø48, is 55, ø51 is 60, ø76 is 80, ø120 is 125, ø145 is 150 (mm) |

![]()

![]()

![]()

![]()

| Ordering Information Sheet | ||||||

| Magnetostrictive Level Sensor | ||||||

| CODE | TYPE | |||||

| A | Standard | |||||

| B | High Temp | |||||

| C | Sanitary(Hygienic) | |||||

| / | CODE | Length | ||||

| 01 | 1000mm(Standard ) | |||||

| 02 | Tube Extension 1000mm~3000mm | |||||

| 03 | Cable Extension Split 1~20000mm | |||||

| / | CODE | Power Supply | ||||

| D | 24V DC±10% | |||||

| / | CODE | Material | ||||

| 1 | SS304(Standard )) | |||||

| 2 | SS316 | |||||

| 3 | Anti-corrosive ,With PTFE Coating | |||||

| / | CODE | Process Connecting | ||||

| G | G1”Thread (Standard)) | |||||

| T | 1”NPT Thread | |||||

| C | Other ( Customer Remark ) | |||||

| F | Flange(Please Remark Flange Spec) | |||||

| / | CODE | Other Parameters | ||||

| A | Normal Temp: ℃ | |||||

| B | Normal Pressure : Kpa | |||||

| C | IP Grade:IP65 | |||||

| D | Explosion-proof :ExdⅡ CT5 | |||||

| E | Max Temp: ℃ | |||||

| F | Max Pressure: Kpa or Mpa | |||||

| () | Other Request | |||||

| / | ||||||

| A | 01 | D | 1 | G | AB (EXAMPLE ) | |