- Have any questions?

- +86 15953537010

- admin@wepower-electronic.com

- Home

- Level Meter

- Magnetic Level Indicator

- Magnetic Tank Level Gauge

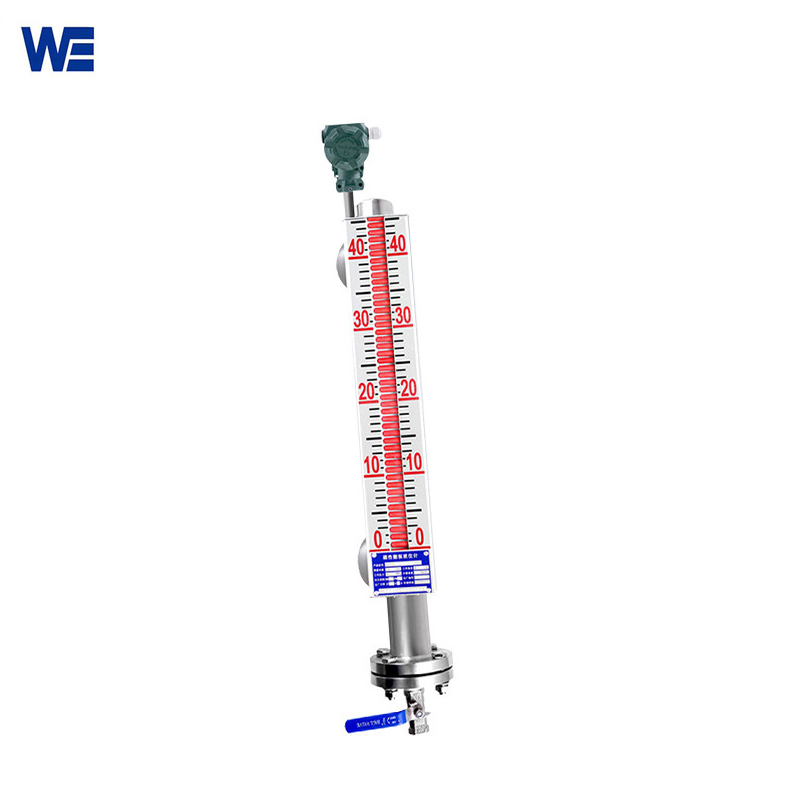

Magnetic Tank Level Gauge

Magnetic tank level gauge can be used for medium level measurement of various towers, tanks, spherical vessels and boilers. The whole process of measurement has no blind spots, the display is eye-catching, and the reading is direct.

![]()

Widely Applications:

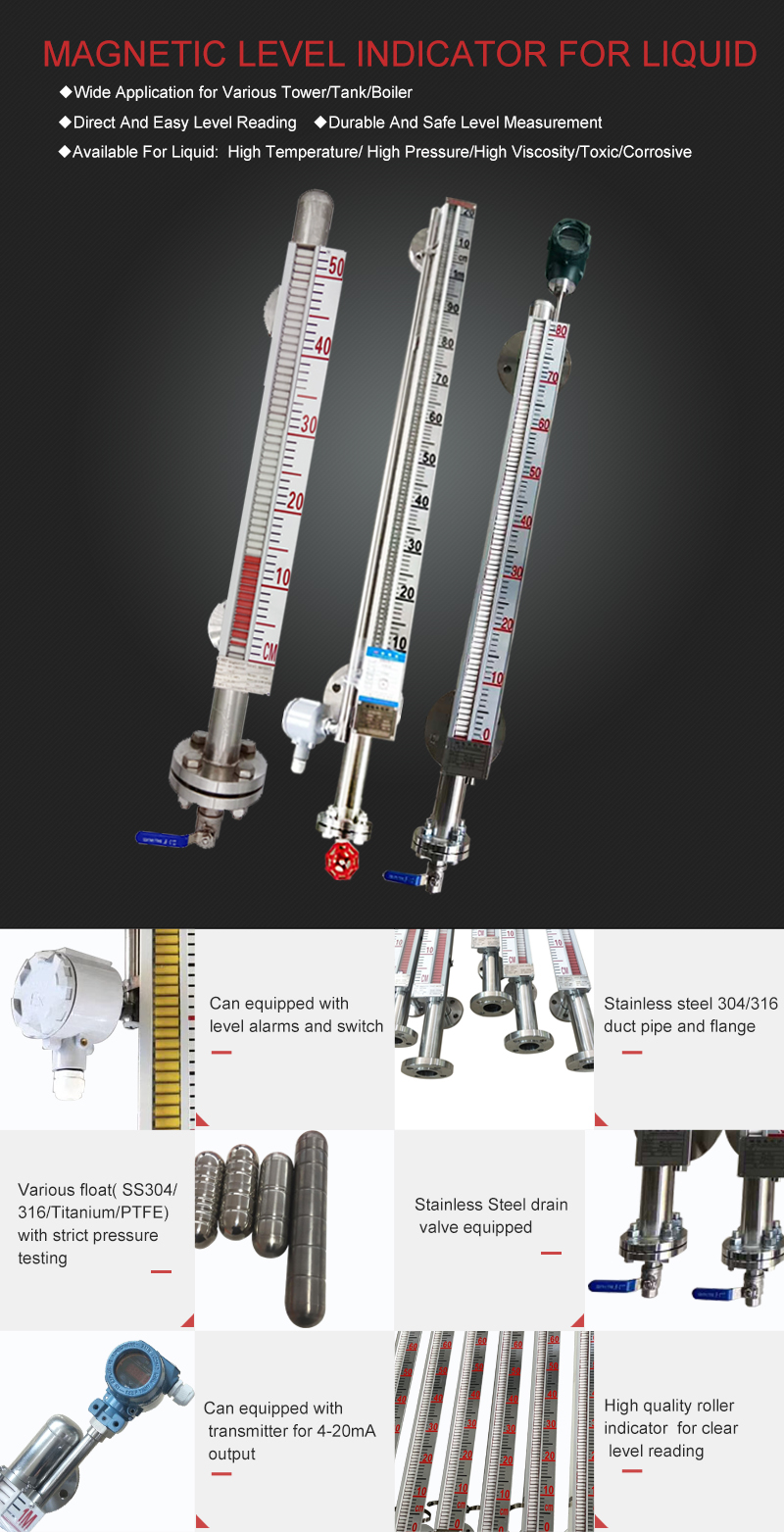

Magnetic Tank Level Gauge can be used for medium level measurement of various towers, tanks, spherical vessels and boilers. The whole process of measurement has no blind spots, the display is eye-catching, and the reading is direct. Especially the on-site indication part, because the magnetic tank level gauge is not in direct contact with the liquid medium, it can show its superiority to high temperature, high pressure, high viscosity, toxic, harmful, and highly corrosive media. Therefore, it is reliable , safe , practical measuring method .

This series of magnetic tank level gauges are widely used for liquid level measurement and control in various production fields such as petroleum, chemical industry, metallurgy, food, and electric power; widely used for liquid tanks such as water storage tank ,rain water tank , fire water tank , diesel fuel tank , concrete water tank ,liquid propane tank etc.

Classification

▲Basic type:

According to the principle of buoyancy, the float moves up and down with the rise and fall of the liquid level in the measuring tube.The long-lasting magnetic steel in the float drives the red and white turning columns to turn 180°through the coupling action. When the liquid level rises, the turning columns turn from white to red, it turns from red to white when descending, so as to realize the liquid level indication.

▲Remote Signal Output:

Install a transmitter on the float magnetic level gauge, move the float up and down, and make the measuring elements in the guide rod act sequentially through magnetic coupling to obtain the resistance signal change, which is converted into a standard signal output of 0-10mA or 4-20mA,and display The instrument or computer is connected to achieve the purpose of remote transmission.

▲Upper and lower limit switch output:

The upper and lower limit positions are set by the user to install the controller on the riser of the level gauge. The controller has a self-holding reed switch. When the reed switch moves with the liquid level, the magnetic float is used to achieve alarm or limit Position control.

![]()

![]()

| Product Name | Magnetic tank level gauge/ Magnetic float level meter |

| Measuring range | 150~15000mm |

| Accuracy | ±10mm |

| Working pressure | Normal pressure~25MPa |

| Working temperature: | -200~600℃ |

| Medium density | 0.5~2.0 g/cm3 |

| Medium density difference | ≥150kg/m3 (measurement boundary) |

| Environmental vibration: | frequency≤25Hz, amplitude≤0.5mm |

| Following speed: | ≤0.08m/s |

| Medium viscosity | ≤0.4Pa.S (jacket heating can be used to improve viscosity conditions) |

| Process connection | flange, or the installation method and specifications specified by the customer |

| Material: | Duct Pipe : 304; 316L; PTFE

Float : 304, 316L, PTFE; Titanium |

Features:

- Strong airtight-ness and not easy to penetrate- this series of products adopt special interface treatment, which is more suitable for high penetration occasions such as liquid ammonia

- High temperature resistance and high pressure ability-the maximum temperature of this series of products can be as high as 500 ℃, and the maximum pressure can reach 26 MPa

- Corrosion resistance-this series of products adopt the new stainless steel lining PTFE process to make the product strong in corrosion resistance

- Can be used in low temperature occasions-this series of products adopts special jacket technology, and can handle the occasions of minus 200 degrees.

- Strong signal remote transmission ability-the signal output of this product can be on-off, analog, and HART protocol

![]()

![]()

| UHZ Magnetic Liquid Level Gauge | ||||||||

| / | A Side Mounted B Top Mounted |

Installation Type | ||||||

| / | 1 Basic Type 2 Anti-corrosive 3 Jacket Type 4.High Pressure &Pressure |

Type | ||||||

| / | C 0.6MPa D 1.6MPa E 2.5MPa F 4.0Mpa G 6.4Mpa H More than 6.4MPA |

Working Pressure | ||||||

| / |

|

Optional | ||||||

| / | L= Measuring Range (For Side Mounted) | / | ||||||

| / | L1=Measuring Range (Top mounted 0~4000mm) | / | ||||||

| / | Medium Density ρ(g/cm3) | / | ||||||

| / | / | |||||||

| A | 1 | D | 1 | L=2500mm | L1=3000mm | ρ=0.8g/cm3 | Example | |