- Have any questions?

- +86 15953537010

- admin@wepower-electronic.com

- Home

- Level Meter

- Magnetostrictive Level Meter

- Interface Level Sensor

Interface Level Sensor

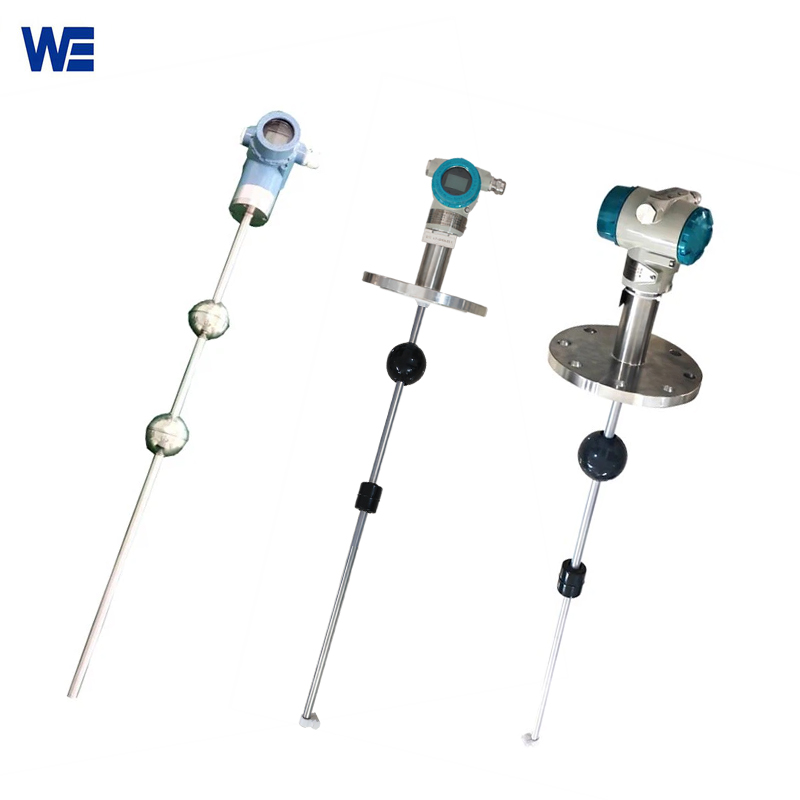

The interface level sensor can be used to monitor the level of two liquids with different specific gravity values. If you are in need, contact Wepower please!

![]()

The interface level sensor monitors the liquid level of two liquids with different specific gravities, is it true?

Yes.The Interface Level Sensor is used to monitor the level of two liquids with different specific gravity values. When two different liquids are in the same tank but cannot mix with each other, an emulsion layer is formed and a barrier is formed between the two liquids. Oil and water are a good example of how when two insoluble substances mix, the heavier liquid(water)sinks to the bottom while the lighter liquid (oil)stays on top. Interface measuremnet between different liquids are very important in some industries ,for example in oil production, water or steam is used to extract oil from a well.

Interface level sensor, as a high-precision continuous automatic instrument for measuring liquid level, is favored by more and more applications. Based on its original work principle, Wepower Electronic has developed and improved its performance to achieve accurate measurement of the interface , and can simultaneously use two floats to detect liquid level and interface. Two 4-20 mA outputs are used for process monitoring ,interface level sensor by magnetostrictive principle is reasonable price with long service life which can give you the accuracy and continuous monitoring to keep operations running.

How dose the interface level sensor monitor the interface?

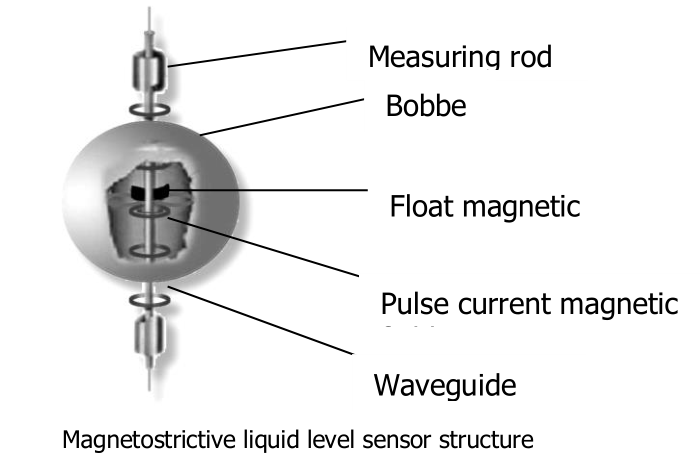

The magnetostrictive effect is used in the magnetostrictive interface measurement technology to take measurements. In order to create a magnetic field surrounding the magnetostrictive line, the detector emits low-current pulses. In addition, the float’s internal magnet creates an exterior magnetic field that surrounds it. In order to detect the oil-water boundary, two magnetic fields must intersect and collide to create a waveguide-distorted pulse. By measuring the time interval between two pulses, the interfacec position of the float is detected.

![]()

![]()

| Product Name | Interface Level Sensor (WPX902) | |

| Output | 2-wire 4-20mA+Hart | Modbus |

| Output parameters | Liquid level, interface, temperature, liquid level difference | |

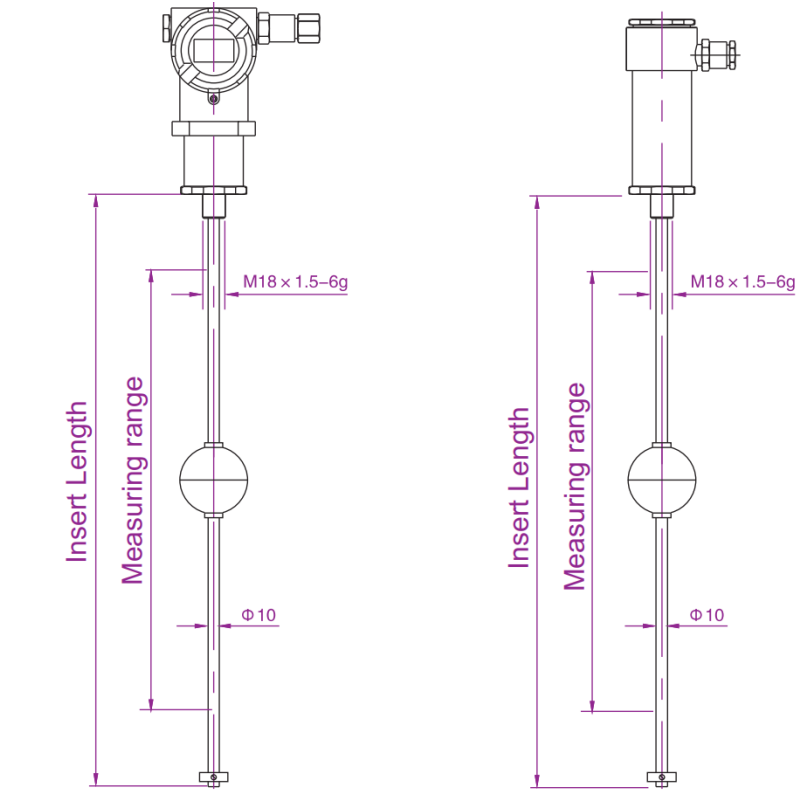

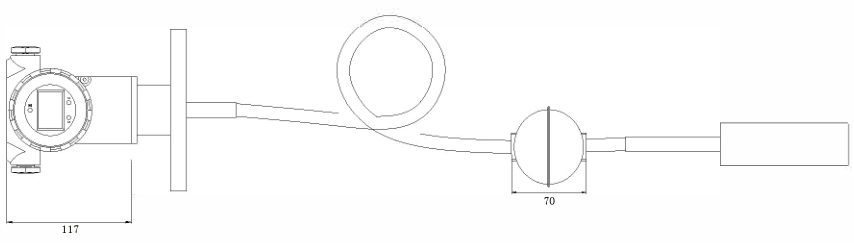

| Effective range | Hard rod: 100~6000mm; flexible rod: 1000~22000mm | |

| Number of measurement points | 1, 2 | 3 |

| Resolution | 16-bit D/A | Up to 0.1mm |

| Non-linear error | ≤ ±0.05% of full scale | |

| Repeatability | ≤ ±0.01% of full scale | |

| Value error | ≤ ±0.1% of full scale | |

| Response time | 100ms | |

| Working voltage | Rated working voltage: 24Vdc; normal working voltage: 10~30Vdc | |

| Operating current | <25mA (varies with range size) | <50mA (varies with range size) |

| Load characteristics | power supply 24V, current output

Maximum load 500Ω |

– |

| Protection class | IP67 | |

| Measurement blind zone | Upper blind zone can be none; lower blind zone minimum 20mm; blind zone of float height | |

| Temperature | Ambient temperature: -40℃~+70℃.

Medium temperature: -40℃~+70℃ (common type); -40℃~+200℃ (high temperature type) |

|

| Electronic housing material | Aluminum alloy, stainless steel 304 | |

| Medium density | ≥500kg/m3 | |

| Material of measuring rod | Stainless steel 304, 316, other materials can be customized | |

| Pressure-bearing characteristics | Rated 1.6mpa, can be customized | |

| Process interface | Thread or Flange | |

| Electrical interface | 2pcs M20*1.5 | |

| Overpressure protection | 36V | |

| Polarity protection | Diode in series | |

| Insulation resistance | 20M(100V) | |

| Dielectric strength | 500V | |

| Other functions | 5-point temperature measurement; with field display and setting function | |

| Explosion-proof mark | Ex d ⅡB T6 Gb | |

![]()

▲Thread:

▲Flange:

▲Cable:

![]()