- Have any questions?

- +86 15953537010

- admin@wepower-electronic.com

- Home

- Tempereaure Measurement

- Temperature Thermometer

- Industrial Bimetal Thermometer

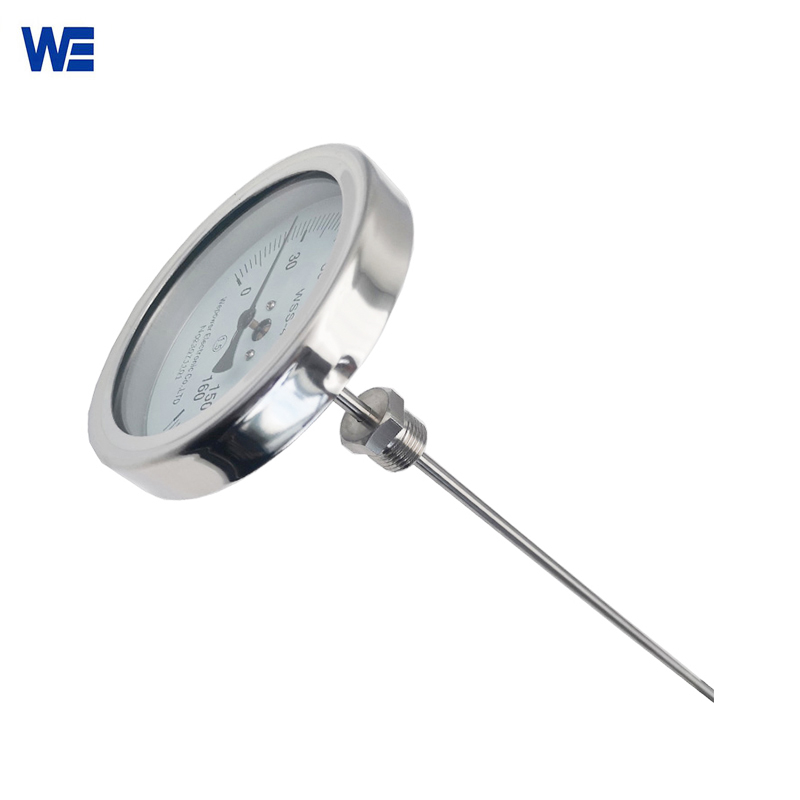

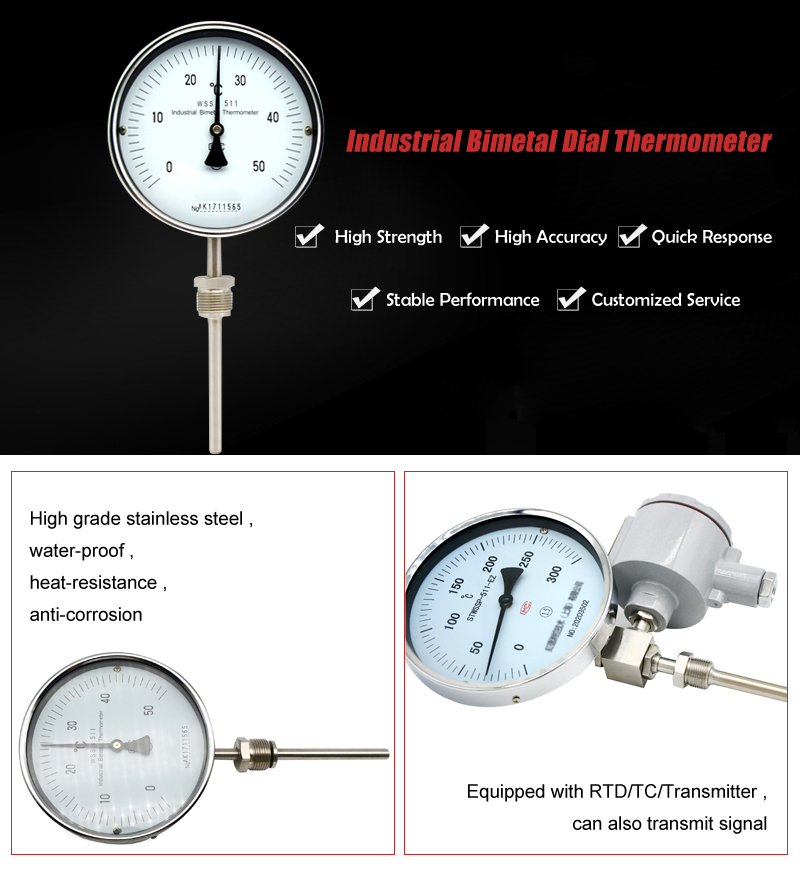

Industrial Bimetal Thermometer

Industrial Bimetal Thermometer combines two metals with different linear expansion coefficients, and one end is fixed, while the temperature changes, the two metals have different thermal expansions, which drive the pointer to deflect to indicate the temperature.

![]()

Working Principle Of Industrial Bimetal Thermometers:

Two metals with distinct linear expansion coefficients are combined in an Industrial Bimetal Thermometer. One end of the thermometer is fixed, and as the temperature varies, the thermal expansions of the two metals cause the pointer to deviate, indicating the temperature. Within the range of 80°C to +500°C, the Industrial Bimetal Thermometer can directly measure a variety of liquid, steam, and gas production processes. When industrial standards for accuracy are not high, the industrial bimetal thermometer can be used to monitor temperature.

Use And Maintenance:

▲Protective tubes should not be bent or deformed when industrial bimetallic gauges are being stored or installed. It is highly prohibited to twist the thermometers’ housing during installation.

▲Bimetal thermometers should work normally within an ambient temperature of -30℃~80℃.

▲The bimetallic gauge’s temperature should fall between 1/2 and 3/4 of the scale range.

▲To guarantee measurement accuracy, the immersed length is larger than 100 mm when the immersion length of the 0–50°C range is greater than 150 mm.

▲Electric contact thermometers are not appropriate for use in the control circuit in situations with significant working vibrations, and different kinds of bimetal thermometers are not appropriate for determining the temperature of the medium in an open container.

▲The thermometer should be inspected regularly under normal use, every six months is appropriate.

▲Clean the thermometer housing and temperature sensing element regularly to remove attached dirt and impurities.

Parameters:

| Product Name | Industrial Bimetal Thermometer |

| Temperature Range | -30…+60,0….100,0…120,0…160,0…200,0…300,

0…350,0…400,0..500,0…600 |

| Material | stainless steel 304/316 |

| Accuracy | 1.5% of range |

| Diameter of Dial Indicator | φ100mm;150mm;75mm;63mm |

| Capillary Material | SS304/SS316 |

| Probe Diameter | φ6, φ10, φ12 |

| Process connecting Method | Without fixed

Movable thread outer Movable thread inner Fixed thread Fixed flange Adjustable thread Adjustable flange |

| Thread | M16X1.5; M27X2; G1/2; G3/4,M33×2 |

| Direction | Axial/Radial |

| Contact Type(for electric contact type): | NO,NC,NONO,NCNC,NONC,NCNO,SPDT |

![]()

![]()

![]()