- Have any questions?

- +86 15953537010

- admin@wepower-electronic.com

- Home

- Flow Meter

- Oval Gear Flow Meter

- Heavy Oil Flow Meter

Heavy Oil Flow Meter

Heavy oil flow meter is a volumetric flow meter mainly used to measure liquids such as heavy oil, lubricating oil, coal tar, polyvinyl alcohol and gasoline. Oval gear flow meter ‘s accuracy and ease of reading satisfy most industrial refining and chemical industries.

![]()

Heavy oil flow meters are commonly used. Heavy oil flow meters are typically installed on pipelines using various connection methods. Within a certain range, the more viscous liquid is more conducive to heavy oil flow meter measurement, according to physics and mechanics. This is why, when measuring with a heavy oil flow meter, more conditions must be met for acid-base liquids with lower viscosity than oils. The flow rate of acid-base liquids can be measured within 30m³/h, whereas oil with higher viscosity can be measured within 340m³/h.

How to remove air bubbles in heavy oil flow meter efficiently?

- Currently, our recommendation is to install a getter filter. In terms of practical application and operation, if the flow rate is rapidly increased in the pipeline at the start, more air bubbles will be generated in the pipeline, causing the measuring element to run at an excessive speed and damaging the shaft and bearing.

- The correct operation method is to gradually increase the flow rate in the pipe when starting the operation, so that the air in the pipe is slowly discharged from the pipe.

- Make sure there are no air bubbles when installing the Heavy oil flow meter. First, the gas will affect the accuracy of the measurement; secondly, our company’s heavy oil flow meter cannot be used to measure the gas, and the air bubbles will affect the volume measurement.

![]()

![]()

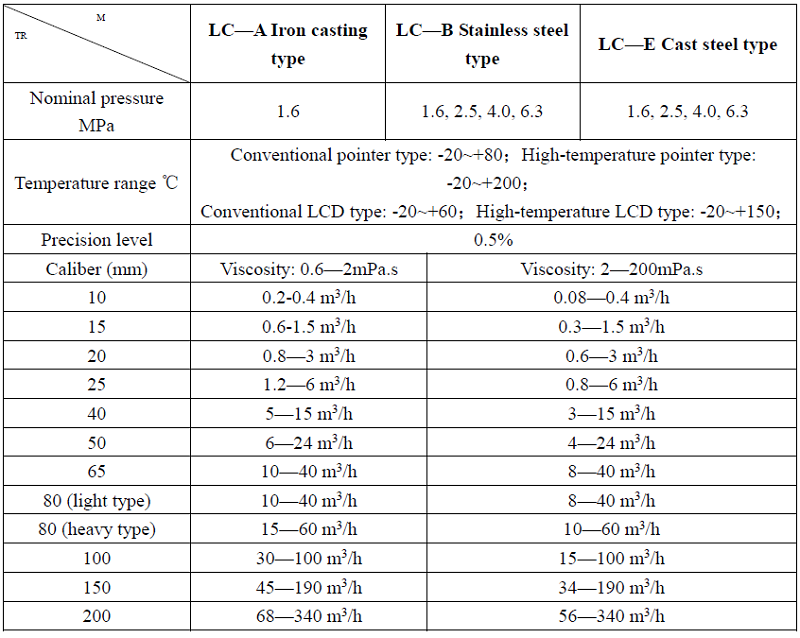

1)Oval gear flowmeter of iron casting type, cast steel type and stainless steel type:

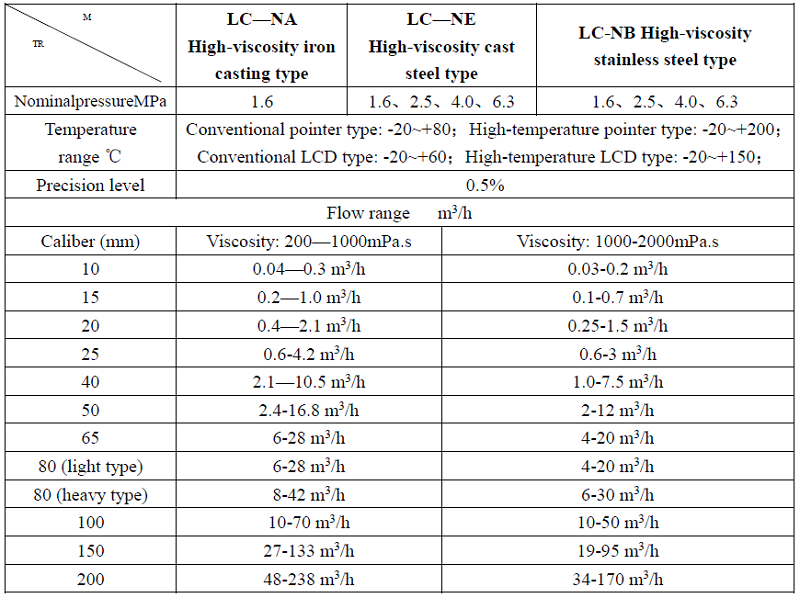

2)Oval gear flowmeter of high viscosity type:

![]()

1.A matching filter shall be installed before the oval gear flowmeter, and the outlet of the matching filter is

connected to the inlet of the flowmeter. The arrow points on both bodies are consistent with the

flow direction of the liquid.

2. When the liquid umder test contains gas, the gas elimination filter should be installed before the

Flowmeter.

3.No matter whether the pipeline is installed vertically or horizontally, the oval gear in the flowmetel

shall be installed in a horizontal position (i.e. the gauge disc shall be perpendicular to the ground).

4. When the flowmeter is properly installed, if it is not easy to read, turn the counter to 180 degrees or

90 degrees.

5. The new flowmeter pushes the elliptical gear several times fiom the exit with a bamboo stick before

installation. If it doesn’t move, soak in diesel oil (Avoid sediment after factory check).

6. Flow control valve should be installed at the inlet of the Flowmeter, and open and close valve is

installed at the outlet. When using open and close valve, start slowly, do not suddenly open to

prevent “water hamer” phenomenon.

7. Before installing the flowmeter on the new pipeline, the pipeline needs to be flushed, and the straight

pipe section (instead of the position of the Flowmeter) is used to prevent welding slag, sundries and

so on from entering the flowmeter.

8. It is strictly forbidden to check the flowmeter of cast iron and steel with water.

9.The flow size of the flowmeter in use shall not exceed the technical requirements. The flowmeter

operates at a maximum flow rate of 50-80%

10.If the tested liguid is chemically corrosive, a flowmeter of stainless steel should be selected

![]()