- Have any questions?

- +86 15953537010

- admin@wepower-electronic.com

- Home

- Pressure Measurement

- Diaphram Pressure Transmitter

- Gold Plated Diaphragm Pressure Transitter

Gold Plated Diaphragm Pressure Transitter

Gold Plated Diaphragm Pressure Transitter is the gold coating diaphragm seal presssure /level transmitter which is specially adopted for hydrogen application. Contact us for more details now !

![]()

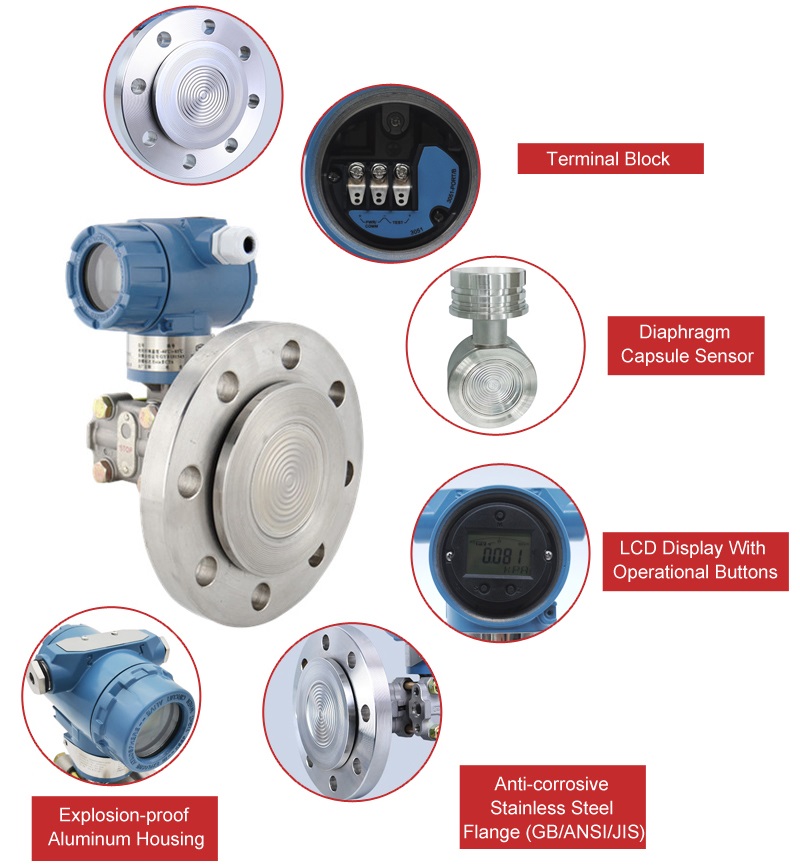

WE3051LT Gold Plated Diaphragm Pressure Transitter is the gold coating diaphragm seal presssure /level transmitter which is specially used for hydrogen application.

The smallest and most prevalent chemical element is hydrogen. Hydrogen is a component of water, acids, bases, and the associated family of organic molecules. Hydrogen is not thought to be corrosive, however under some conditions, issues with pressure transmitters installed with diaphragm seals can still arise. For instance, if high process temperatures are combined with either high process pressure, a galvanic reaction, or high temperature steam, this could lead to hydrogen permeation of the into H+ splitted H2 molecules.Wepower Electronic provides a remedy for this circumstance by using a unique substance- covering of gold plated on the diaphragm seals.

Except used for hydrogen , gold plated diaphragm pressure transitter can be also used for the anti-corrosion application too . Wetted diaphragm materials are 316L, Hastelloy C-276, Monel, tantalum, etc., which can be applied to the anti-corrosion requirements of different situations and can be based on the measured medium concentration, humidity, pressure and other parameters .

![]()

| Product Name | Gold Diaphragm Pressure Transitter |

| Process Fluid : | Liquid, Gas or Vapor |

| Application: | Liquid Level, Differential Pressure, Gauge Pressure, Absolute Pressure |

| Material | Flange : Carbon steel/ Stainless Steel 304/ Stainless Steel 316 |

| Diaphragm : Gold ;Stainless Steel 316L/ Hastelloy B/ Hastelloy C/ Tantalum/ PTFE-coated Tantalum Diaphragm | |

| Capillary : Stainless Steel with PVC coating | |

| Flange Size | 40mm, 50mm, 80mm, 100mm, 1-1/2″, 2″, 3″, 4″ |

| Flange Rating | JIS 10K / JIS 20K / JIS 40K |

| ANSI 150# / ANSI 300# / ANSI 600# | |

| DIN PN10 / PN16 / PN25 / PN40 | |

| Tri Clamp (DIN32676 / ISO2852) | |

| Installation Style | Direct-mount: RD/ One-sided Capillary: RD1/ Two-sided Capillaries: RD2 |

| Capillary Length | 1.0 M ~ 10 M |

| Time Response | Less than 1.12 seconds |

| Accuracy | +/-0.15% of Span |

| Extension Length | 2″, 3″, 4″ |

| Fill Fluid and Maximum : | Silicone (Max. Temperature 130 °C) |

| Max. Temperature | Direct-Mount : -20 to 80 °C |

| Remote Diaphragm : -40 to 280 °C | |

| Max. Pressure | 8.0MPa |

| Stability | +/-0.15% of URL for 2 years |

![]()

![]()

![]()

![]()

![]()

| WE3051RD Series | ||||||||||||||||||

| Example: WERD2-A22B4-N05-W | ||||||||||||||||||

| KDRD | X- | X | X | X | X | X | -X | XX | -X | Description | ||||||||

| Installation Style | RD- | / | Direct-mount | |||||||||||||||

| 1- | One-sided Capillary Connects Remote Diaphragm Seal | |||||||||||||||||

| 2- | Two-sided Capillaries Connect Remote Diaphragm Seal (RD2 Only) | |||||||||||||||||

| Process Connection | 1 | / | PN10 | |||||||||||||||

| 2 | PN16 | |||||||||||||||||

| 3 | PN25 | |||||||||||||||||

| 4 | PN40 | |||||||||||||||||

| A | ANSI 150# | |||||||||||||||||

| B | ANSI 300# | |||||||||||||||||

| J | JIS 10K | |||||||||||||||||

| K | JIS 20K | |||||||||||||||||

| L | JIS 40K | |||||||||||||||||

| T | Tri-clamp (DIN32676 / ISO2852) | |||||||||||||||||

| Z | Other | |||||||||||||||||

| Flange Size | 1 | / | 1-1/2″ (Diaphragm Diameter If Extended: 38mm) | |||||||||||||||

| 2 | 2″ (Diaphragm Diameter If Extended: 48mm) | |||||||||||||||||

| 3 | 3″ (Diaphragm Diameter If Extended: 66mm) | |||||||||||||||||

| 4 | 4″ (Diaphragm Diameter If Extended: 89mm) | |||||||||||||||||

| Diaphragm Extension Length | 0 | / | Flush Diaphragm | |||||||||||||||

| 2 | 2″ (50mm) | |||||||||||||||||

| 4 | 4″ (100mm) | |||||||||||||||||

| 6 | 6″ (150mm) | |||||||||||||||||

| Diaphragm Material | N | / | Stainless Steel 316L | |||||||||||||||

| B | Hastelloy B | |||||||||||||||||

| C | Hastelloy C | |||||||||||||||||

| T | Tantalum | |||||||||||||||||

| P | PTFE-coated Tantalum Diaphragm (PTFE Thickness:40μm) | |||||||||||||||||

| Z | Other | |||||||||||||||||

| Flange Material | N | / | Carbon Steel | |||||||||||||||

| 4 | Stainless Steel 304 | |||||||||||||||||

| 6 | Stainless Steel 316 | |||||||||||||||||

| Z | Other | |||||||||||||||||

| Fill Fluid | -N | / | Silicone (Max. Temperature 130 °C) | |||||||||||||||

| -S | HT Silicone (Max. Temperature 280 °C) | |||||||||||||||||

| -F | Fluorine (Max. Temperature 160 °C) | |||||||||||||||||

| -V | Vegetable Oil (Max. Temperature 130 °C) | |||||||||||||||||

| Capillary Length | NN | / | Direct-Mount | |||||||||||||||

| 01-10 | 1 M ~ 10 M | |||||||||||||||||

| Option | – N | None | ||||||||||||||||

| – W | Oil-free and Water-free Treatment | |||||||||||||||||