- Have any questions?

- +86 15953537010

- admin@wepower-electronic.com

- Home

- Level Switch

- Vibration Fork Level Switch

- Fork Type Level Switch

Fork Type Level Switch

This fork type level switch is compact switch with durable stainless steel body, can be used for a variety of liquid applications.

![]()

Feature Of Fork Type Level Switch:

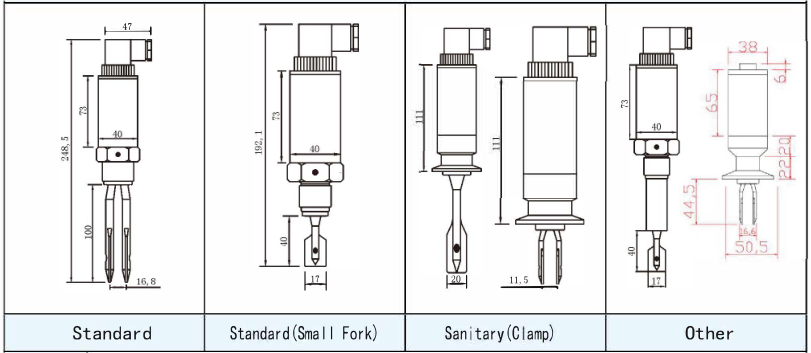

This Fork Type Level Switch is compact fork level switch with durable stainless steel body, can be used for a variety of liquid applications, The overall structure of this fork type level switch is compact and lightweight. The total length of the fork type level switch is 160.5mm, the maximum diameter is 31.5mm.

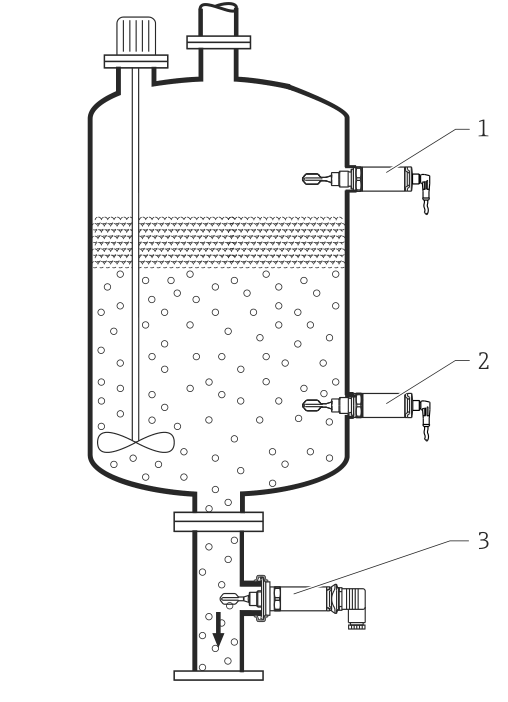

In addition to being appropriate for measuring liquid levels in storage tanks, containers, bubble-filled tanks, tanks with viscous liquids, and tanks with vibration interference, fork type level switches can also be used to monitor liquid levels in tiny containers and in tight spaces surrounding tanks. The device can measure the medium’s density as low as 0.7g/cm³ and is designed to detect changes in vibration frequency when the fork is submerged in the medium.

| Measure Medium | Liquid |

| Vibrational Frequency | 350/1000HZ |

| Accuracy | ±2mm |

| Fork Length | 40mm or 100mm |

| Measuring Length | 40-1000mm |

| Ambient Temperature | -30-80℃ |

| Operation Temperature | -30-150℃ |

| Repeatability | ±2mm |

| Indication Method | LED |

| Power Supply | 24V DC |

| Power | 1 W |

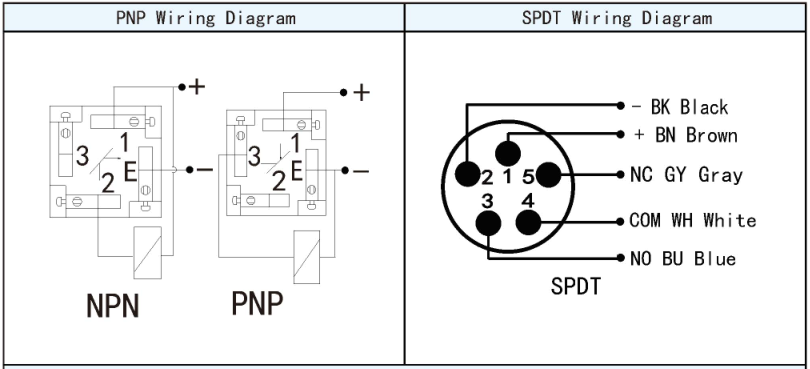

| Signal Output | SPDT/PNP/NPN/NAMUR |

| Body Material | Stainless steel |

| Pressure Range | -98KPa-3MPa |

| Wetted material | SS304/SS316 |

| Process Connecting | Thread, Tri-clamp |

| Electrical Interface | Hersman Joint / Aviation Joint |

![]()

Product Dimension

Installation Guidance

Installation method of compact fork type level switch:

Before installation, you should reconfirm whether the model meets the environmental requirements of the site (such as: process pressure, process temperature, chemical properties of the medium, etc.) to ensure that the instrument can be used normally after installation.

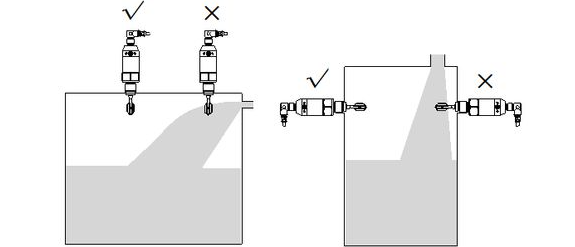

Generally, the compact fork type level switch can be installed in any position as required, and can be installed horizontally, vertically or obliquely. But when the measured medium is relatively viscous, in order to reduce or avoid the phenomenon of hanging materials, the meter should be installed vertically.

- Installation Direction

When installing the compact tuning fork type level switch, the fork body surface and the liquid lifting or flow should be kept in the same direction, so as to avoid the measurement error caused by the resistance of the medium to the fork body.

2.Avoid The Inlet

When choosing the installation position of the compact tuning fork liquid level switch, avoid measurement errors caused by installation at the feed inlet position, or even damage to level switch .

![]()

![]()