- Have any questions?

- +86 15953537010

- admin@wepower-electronic.com

- Home

- Tempereaure Measurement

- RTD Sensor

- Explosion-proof RTD

Explosion-proof RTD

Explosion-proof RTD produced by Wepower Electronic has high temperature measurement accuracy, high mechanical strength, good voltage resistance, and imported thin film resistor elements, with reliable and stable performance. If you have any customization needs, feel free to contact us please.

![]()

Explosion-proof RTD designs components like junction boxes with enough strength to seal all sections that produce sparks, arcs, and harmful temperatures in the junction box cavity using the gap and explosion-proof design principles. In the event that the cavity explodes, it can pass in order to prevent the flame and temperature from escaping the cavity following the explosion, the joint surface gap is cooled and extinguished.

Features & Advantages Of Explosion-proof RTD:

- The housing has high hardness, explosion-proof and durable, not easy to damage, no leakage risk, and strong anti-interference ability;

- Good sealing performance, with a customized protective ring at the seal to isolate moisture and water vapor from entering and protect the internal circuit from corrosion;

- Shock-resistant and stable, long life;

- Imported high-quality chips, strong stability

Application Areas:

Explosion-proof RTD is widely used in Oil and Gas Field Drilling Platforms, Power Grid, Natural Gas Chemical Industry, Thermal Power Generation, Steel Smelting and Petrochemical Industry.

Parameters:

| Product Name | Explosion-proof RTD |

| Ref No. | PT100/PT500/PT1000 |

| Thermal Element Materials | Platinum |

| Explosion-proof grade: | DIIBT4/ DIICT6 |

| Accuracy Class | 1/3B

A B |

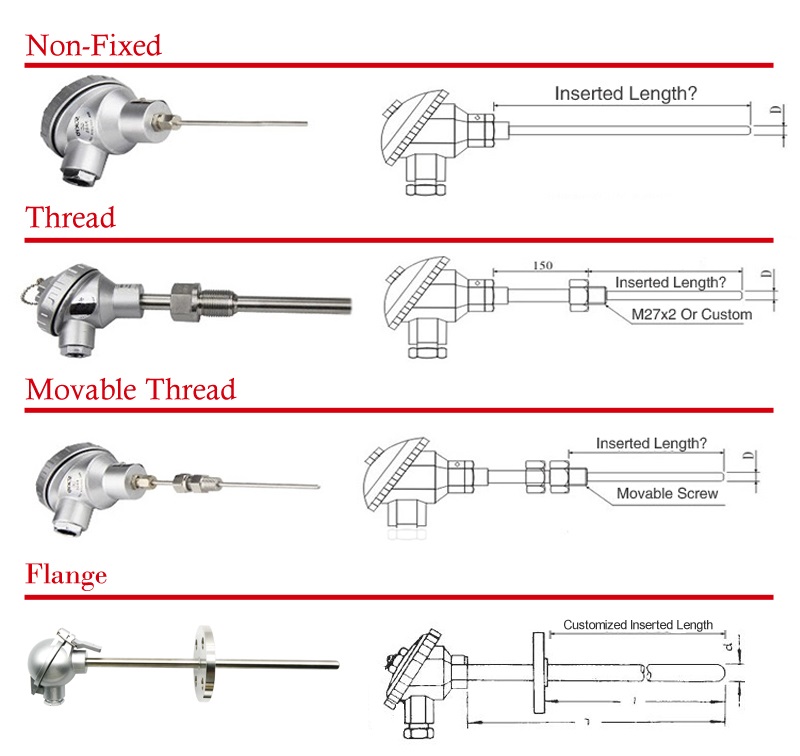

| Ways of Mounting & Fixing | 1: Without fixing device 2: Fixed compression thread 3: Movable compression thread 4: Fixed compression flange 5: Movable compression flange 6: Shock-resistant & Anti-leakage compression thread |

| Types of connections box | 1: Connection seat type 2: Anti-spray (Protection class: IP65) 3: Water-proof (Protection class: IP67)4:Round plug type5: Flag plug type6:Small Connection type7:Compensation wire type |

| Diameter of protective tube | Ø16 ,Ø12, Ø3, Ø4,Ø5, Ø6, Ø8 |

| Protecting sheath material | ICr18Ni9Ti/304/316/316L/C-276/Monel |

| Measuring range | -200~500 degrees Celsius |

| Thread | 27*2 (6mm 8mm 10mm 12mm 16mm can be customized) |

| Shipping | By air, sea, express |

| Sample time | 2~5 days |

| Manufacture time | 7~30 days depending on order quantity |

![]()

![]()