- Have any questions?

- +86 15953537010

- admin@wepower-electronic.com

- Home

- Pressure Measurement

- Pressure Transmitter(WE3051)

- Digital Pressure Transmitter With Hart

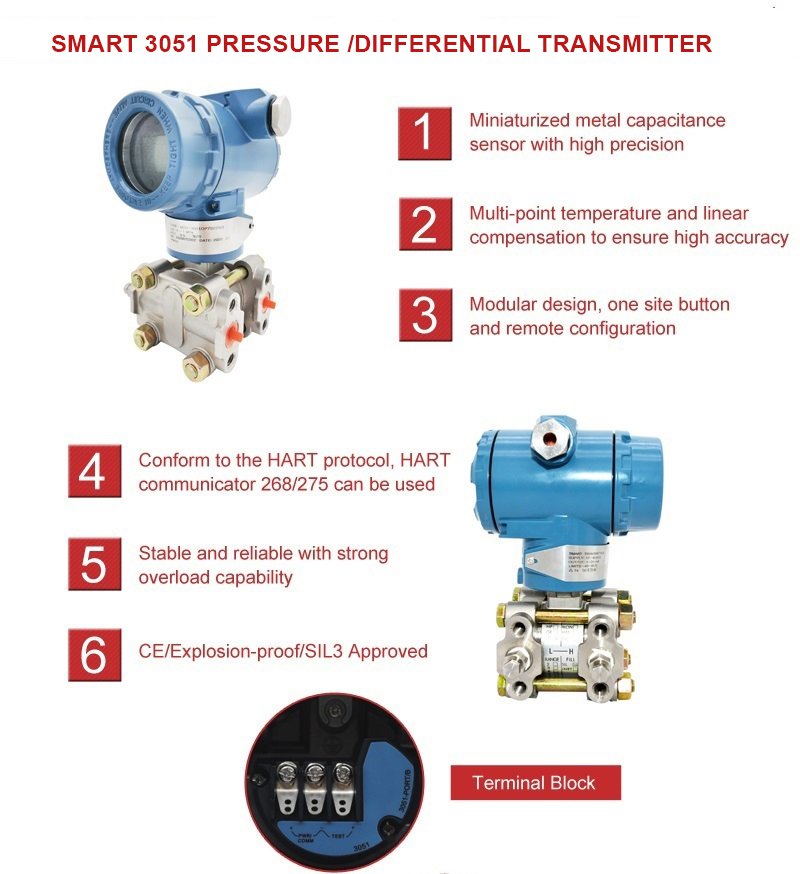

Digital Pressure Transmitter With Hart

3051DP/DTP Digital pressure transmitter With Hart has various varieties and specifications, good stability and high reliability. Digital pressure transmitter with Hart can generally be measured under static pressures of 4, 10, 25, and 35MPa. The accuracy of the differential pressure digital pressure transmitter is about ±0.1-0.2%.

![]()

3051DP/DTP Digital pressure transmitter With Hart has various varieties and specifications, good stability and high reliability. Digital pressure transmitter with Hart can generally be measured under static pressures of 4, 10, 25, and 35MPa. The accuracy of the differential pressure digital pressure transmitter is about ±0.2%. Generally speaking, there is no measurement blind spot.

Digital pressure transmitter is a differential pressure transmitter, the principle of operation has six important steps, first of all, the diaphragm of the sensor senses the pressure change of the medium, then the sensor accepts the information and transmits the signal to the outside, then the site will analyze the signal and concern the command to execute, and finally the actuator will operate according to the command.

One of the highlights of the WE 3051DP/DPT digital pressure transmitter is that when the temperature changes, the volume of the oil material expands or shrinks, but the impact on the pressure difference is very small, and the pressure detected by the differential pressure transmitter is always changeless.

![]()

| Sensor Type | Smart Differential Pressure Transmitters ( Digital 3051DP /DPT digital pressure transmitter ) |

| Accuracy | ±0.1% |

| Medium | Liquids, steam and gas |

| Stability | 0.2% |

| Measuring Range | 0~1.5, 0~7.5, 0~37.4, 0~186.8, 0~690, 0~2068 |

| Explosion-proof Type | General type, Exd II C T6 Gb, Exia II C T6 Ga |

| Output Signal | 4-20mA DC, HART |

| Diaphragm Material | SS316L, Hastelloy C, SS316L |

| Diaphragm Fluids | Silicone oil, fluorine oil |

| Drain hole location | Rear face of process flange, Upper side of process flange, Lower side of process flange |

| Process Flange and Bolts | Stainless steel or carbon steel |

| Process flange O-ring material | Buna-N (NBR), Fluorine rubber (FKM) (not below -20 degrees Celsius) |

| Process Connections | NPT1/4 inner bolt |

| Static Pressure | 14Mpa (range2 =4Mpa; range3=7Mpa) /25Mpa/32Mpa |

| Power Supply | 9-32 V DC |

| Bracket | None, Tube mounted bend bracket (carbon steel), Wall mounted bracket (carbon steel), Tube mounted flat bracket (stainless steel), Wall mounted bracket (stainless steel), Tube mounted flat bracket (stainless steel) |

![]()

What is the opening position of the differential pressure transmitter’s pressure port while sensing gas, liquid, and steam?

1. When measuring gas, the pressure taking port should be in the upper half of the pipeline to prevent a little amount of condensate in the gas from entering the measuring pipeline and the interior of the instrument.

2. The position of the pressure inlet opening should preferably be at an angle of 0 to 45 degrees below the horizontal middle line of the pipeline when measuring liquid in order to allow a small amount of gas precipitated in the liquid to return to the process pipeline smoothly without entering other positions.

3. When measuring the steam medium, the pipeline should contain a steady condensate, and the pressure tap should ideally be between 0 and 45 degrees above the pipeline’s horizontal centerline.

![]()

![]()

![]()

![]()

- Send us inquiry for more details. Click photo below to learn more our pressure measuremnet products !

- Wepower Electronic is constantly in the lead for the greatest quality and service ! Contact us now!