- Have any questions?

- +86 15953537010

- admin@wepower-electronic.com

- Home

- Pressure Measurement

- Diaphram Pressure Transmitter

- Diaphragm Seal Level Transmitter

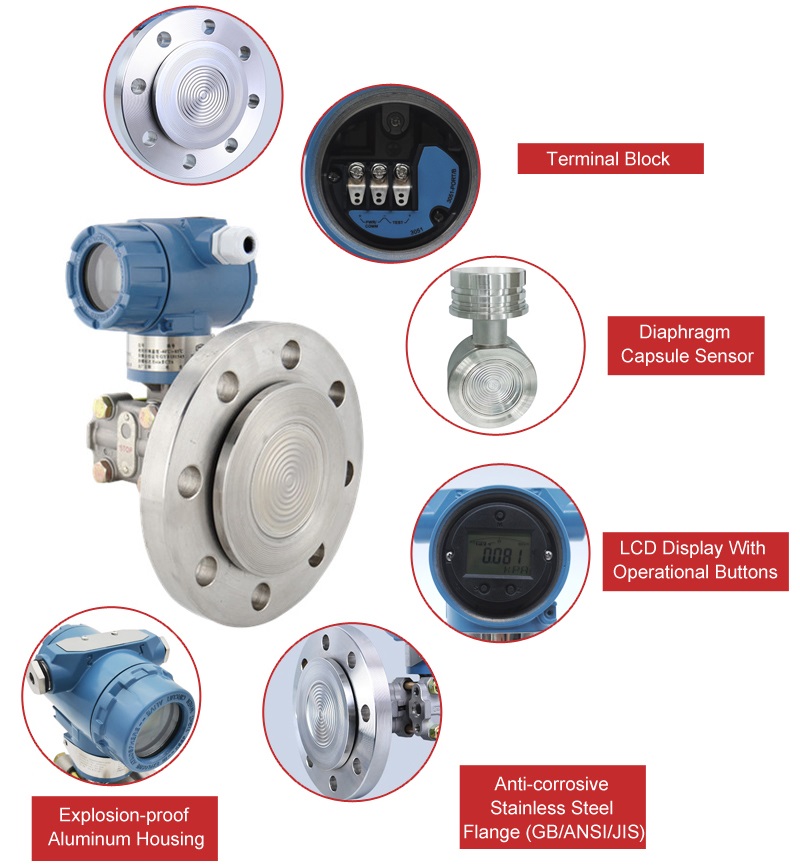

Diaphragm Seal Level Transmitter

WE3051 Diaphragm Seal Pressure Level Transmitter is smart choice for viscous medium at high temperature, easy to crystallize medium, precipitation medium with solid particles or suspended matter, strong corrosive or highly toxic medium can eliminate the leakage of pressure pipe .While in the production of food, beverage and pharmaceutical industries, it is not only required that the parts of medium contacting is hygienic standards, but also it should be easy to wash to prevent cross-contamination of different batches of media.

![]()

WE3051LT Diaphragm Seal Pressure Level Transmitter series is mainly used for measurement in the following occasions: viscous medium at high temperature, easy to crystallize medium, precipitation medium with solid particles or suspended matter, strong corrosive or highly toxic medium can eliminate the leakage of pressure pipe ,the continuous accurate measurement interface and density,occasions that require high hygiene and cleanliness,etc .While in the production of food, beverage and pharmaceutical industries, it is not only required that the parts of medium contacting is hygienic standards, but also it should be easy to wash to prevent cross-contamination of different batches of media. Diaphragm seal pressure level transmitter plays an important roles in those occasions mentioned above , Wepower Electronic has been offering the high grade china made WE3051LT product since the year 2003.

![]()

● 0.1% accuracy

● Parameter setting by keypad directly

● 4-20 mA output plus direct digital HART communication Automatic zero calibration by push-button

● Explosion proof and weather proof housing

● Improved performance, increased accuracy and greater stability Two years stability of 0.15%

● Silicone oil divergent injection technology.

● There are multiple choices of 316 diaphragm, HC and titanium diaphragm.

● The mature built-in metal capacitance sensor ensures good consistency.

● Advanced welding technology to ensure long-term stable operation of high temperature and high pressure silicone oil does not leak.

● Built-in digital temperature transmitter, formatted and tested before leaving the factory, with extremely low temperature influence.

● Support the upgrade to fieldbus and technology based on field control.

![]()

● Process Fluid: Liquid

● Display: 5 Digits programmable & 0-100% Bargraph

● Application: Liquid Level, Differential Pressure, Gauge Pressure, Absolute Pressure

● Measuring Range: 0 – 6.0 kPa ~ 0 – 40 kPa (Minimum)

● 0 – 4.0 MPa ~ 0 – 10.0 MPa (Maximum)

● Accuracy: +/- 0.1% of span

● output setting Current Output:4 – 20 mA 2 wires with Hart Signal

● Working Temperature : -40 to +250 °C

● Power Supply: 9 – 36 VDC

● Max. Pressure: 10 MPa (Dependent on flange rating)

● Digital Communication : Hart Protocol

● Material: Flange: Stainless Steel 316 / Stainless Steel 304

● Diaphragm : Stainless Steel 316L / Hastelloy B / Hastelloy C / Monel / Tantalum

● Threads Bolts & Nuts : Carbon Steel / Stainless Steel 304

● Converter Housing : Low copper cast aluminum alloy

● Fill Fluid : Silicone

● Process connection![]() : High Pressure Side : 1-1/2″, 2″, 3″, 4″ flange ANSI / DIN / JIS / Tri-Clamp

: High Pressure Side : 1-1/2″, 2″, 3″, 4″ flange ANSI / DIN / JIS / Tri-Clamp

● Extended Diaphragm : 2″, 4″, 6″ length

● Low Pressure Side : 1/4″ – 18 NPT , 1/2″ – 14 NPT

● Protection Class: IP67 (Standard)

● Intrinsically Safe EEx ia IIC T5 (Standard)

● Explosion proof Ex D IIB T5

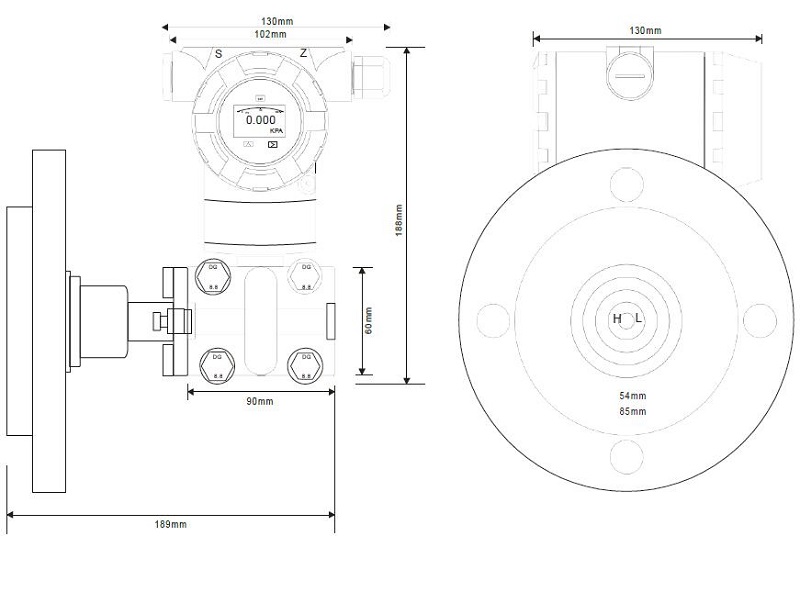

● Dimensions: 102 mm (W) * 188 mm (H) *189 mm (D)

● Weight: 8 – 15 Kg

![]()

![]()

![]()

![]()

![]()

| WE3051LT Series | |||||||||||

| Example: WE3051LT-4A30N-4NN-NN-EX/HT | |||||||||||

| Code | Description | ||||||||||

| Pressure Range | 4 | / | 0 – 6.0 (0.4) kPa … 0 – 40 kPa | ||||||||

| 5 | 0 – 40 (2.0) kPa … 0 – 200 kPa | ||||||||||

| 6 | 0 – 160 (10.0) kPa … 0 – 1000 kPa | ||||||||||

| 7 | 0 – 400 (25.0) kPa … 0 – 2500 kPa | ||||||||||

| 8 | 0 – 1.6 (0.08) MPa … 0 – 8.0 MPa | ||||||||||

| 9 | 0 – 4.0 (0.20) MPa … 0 – 20 MPa | ||||||||||

| Process Connection | 1 | / | PN10 | ||||||||

| 2 | PN16 | ||||||||||

| 3 | PN25 | ||||||||||

| 4 | PN40 | ||||||||||

| A | ANSI 150# | ||||||||||

| B | ANSI 300# | ||||||||||

| J | JIS 10K | ||||||||||

| K | JIS 20K | ||||||||||

| Z | Other | ||||||||||

| Flange Rating | 1 | / | 1-1/2″ (Diaphragm Diameter If Extended: 38mm) | ||||||||

| 2 | 2″ (Diaphragm Diameter If Extended: 48mm) | ||||||||||

| 3 | 3″ (Diaphragm Diameter If Extended: 66mm) | ||||||||||

| 4 | 4″ (Diaphragm Diameter If Extended: 89mm) | ||||||||||

| Diaphragm Extension Length | 0 | / | Flush Diaphragm | ||||||||

| 2 | 2″ (50mm) | ||||||||||

| 4 | 4″ (100mm) | ||||||||||

| 6 | 6″ (150mm) | ||||||||||

| Diaphragm Material | N | / | Stainless Steel 316L | ||||||||

| B | Hastelloy B | ||||||||||

| C | Hastelloy C | ||||||||||

| T | Tantalum | ||||||||||

| Flange Material | -N | / | Carbon Steel | ||||||||

| -4 | Stainless Steel 304 | ||||||||||

| -6St | Stainless Steel 316 | ||||||||||

| Low Pressure Side Process Connection | N | / | 1/4″ – 18 NPT | ||||||||

| A | 1/2″ – 14 NPT(with Adapter) | ||||||||||

| Z | Other | ||||||||||

| Bolts / Nuts Material | N | / | Carbon Steel | ||||||||

| S | Stainless Steel | ||||||||||

| Fill Fluid | -N | / | Silicone (Max. Temperature 130 °C) | ||||||||

| -S | HT Silicone (Max. Temperature 250 °C) | ||||||||||

| -F | Fluorine (Max. Temperature 160 °C) | ||||||||||

| -V | Vegetable Oil (Max. Temperature 130 °C) | ||||||||||

| Cable Entry | N | / | M20 Conduit Threads | ||||||||

| P | 1/2″ NPT (Female) | ||||||||||

| Z | Other | ||||||||||

| Option | -NN | None | |||||||||

| -EX | Explosion Proof Ex D IIB T5 | ||||||||||

| -S6 | Stainless Steel 316 Name Plate and Tag Plate | ||||||||||

| -HT | Hart Signal (Compatible) | ||||||||||

| -ZZ | Others | ||||||||||