- Have any questions?

- +86 15953537010

- admin@wepower-electronic.com

- Home

- Tempereaure Measurement

- Thermocouple Sensor

- Armored Thermocouple Sensor

Armored Thermocouple Sensor

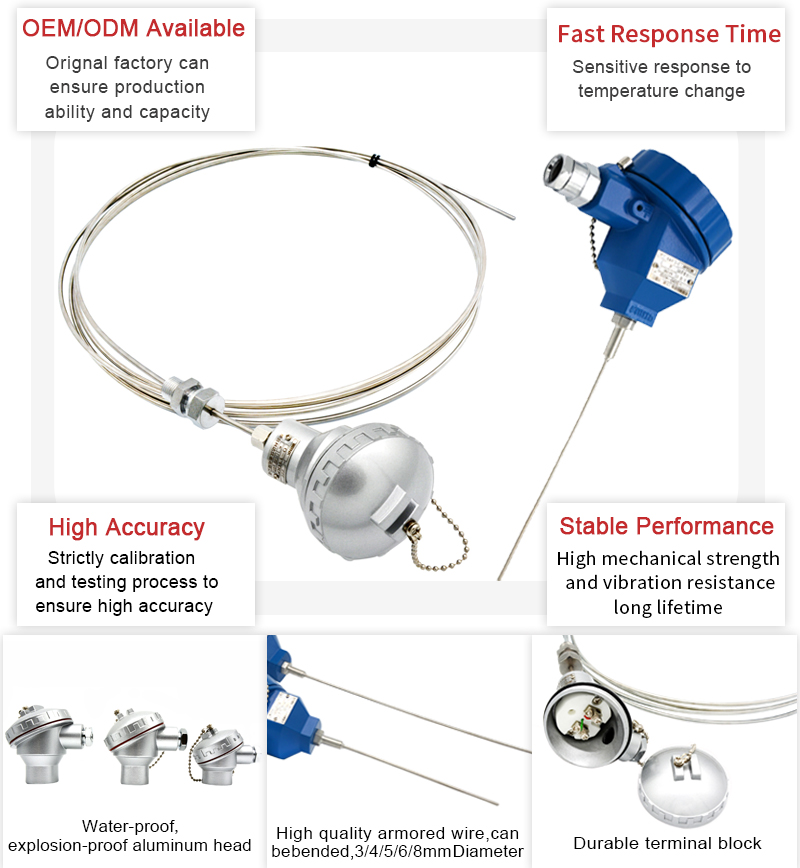

Armored Thermocouple Sensors produced by Wepower Electronic have high mechanical strength, high shock resistance, high pressure resistance, fast thermal response time, durable aluminum shell is waterproof and oil-proof, and has a long service life.

![]()

Flexibility, high pressure resistance, quick thermal reaction time, and durability are all benefits of Armored Thermocouple Sensors. In high-temperature settings, they are typically employed to measure or regulate the temperature of solid surfaces, steam, fluids, and gas media. The temperature can be measured between 0°C and 1800°C. These features are not present in normal thermocouples. Armored Thermocouple Sensor adopt integral terminal block wiring which are available for single or dual J, K, E, T, N, R, S. The protecting rigid sheath can be customized to different diameter

Features Of Armored Thermocouple Sensor:

▲Less thermal response time, reducing dynamic error;

▲ Flexible installation and use;

▲High mechanical strength and good pressure resistance;

▲Small diameter (1, 1.5, 2, 3, 4, 5, 6, 8mm) and the length is not limited;

▲Index number: K, E, S, N, T, J;

▲Aluminum Housing is water-proof ,Explosion-proof.

Parameters:

| Category | Code | Graduation Mark | Extermal diameter of tube(mm) | Common temperature (°C) | High operating temperature (°C) | Allowable deviation | |

| Measuring range (°C) | Allowable difference | ||||||

| Platinum rhodium 10-platinum | WRPK | S | ≥Φ3 | 1100 | 1200 | 0-1200 | ±1.5°C or ±1.5%t |

| Nickel-chromium-copper-nickel | WREK | E | ≥Φ3 | 600 | 700 | 0-700 | ±2.5°C or ±0.75%t |

| Nickel-chromium-nickel silicon | WRNK | K | ≥Φ3 | 800 | 950 | 0-900 | ±2.5°C or ±0.75%t |

| Copper-copper nickel | WRCK | T | ≥Φ3 | 350 | 400 | Less than -200 | Unspecified |

| -40-350 | ±0.75%t | ||||||

| Iron-copper nickel | WRFK | J | ≥Φ3 | 500 | 600 | 0-600 | ±2.5°C or ±0.75%t |

![]()

![]()