- Have any questions?

- +86 15953537010

- admin@wepower-electronic.com

- Home

- Tempereaure Measurement

- Thermocouple Sensor

- Adjustable Spring Thermocouple Probe

Adjustable Spring Thermocouple Probe

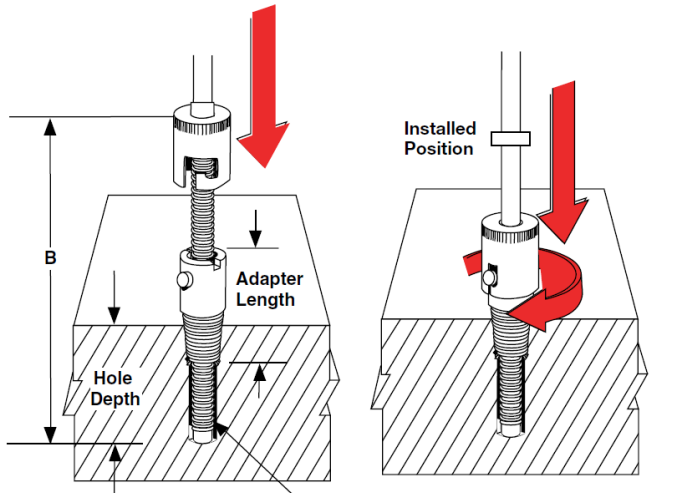

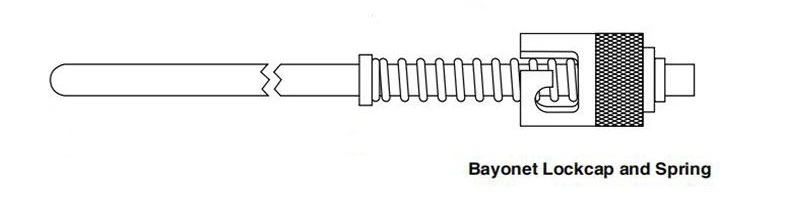

A bayonet fastening cap and a compression spring are included with the adjustable spring thermocouple probe; the bayonet cap can be adjusted on the spring to facilitate site process connection.

![]()

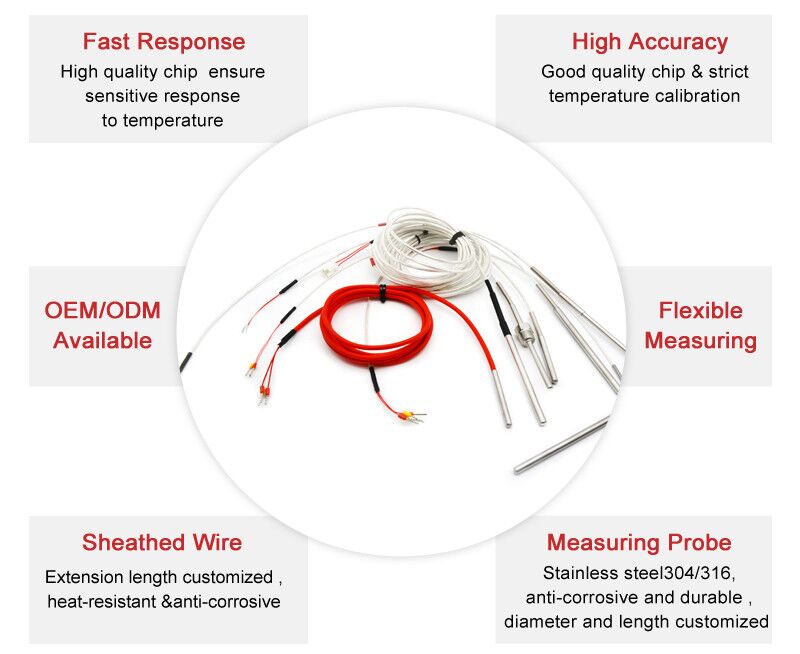

Features Of Adjustable Spring Thermocouple Probe:

To make field process connection easier, the Adjustable Spring Thermocouple Probe’s bayonet cover may be adjusted on the spring. The spring is compressed and secured with the bayonet cover once the sensor has been inserted into the adapter. This process can be applied to single or double J, K, E, T, and N thermocouples. The Adjustable Spring Thermocouple Probe’s primary benefit is its ability to be pushed against a surface, which increases accuracy and reduces response time.

Parameters:

S/E/K/J/T type thermocouple temperature range and accuracy sheet

| Category | Type of sensing element | Sheath diameter | Normal working temperature | Highest working temperature | Allowable deviation △t | |

| Measuring range | Permissible deviation | |||||

| Platinum Rhodium10-Platinum | S type | ≥Ф3mm | 1100℃ | 1300℃ | 0-1300℃ | ±2.5℃ or ±0.75%t |

| Nicklchromium-Copper nickel | E type | ≥Ф3mm | 600℃ | 700℃ | 0-700℃ | ±2.5℃ or ±0.75%t |

| Nicklchromium-Nicel silicon | K type | ≥Ф3mm | 800℃ | 950℃ | 0-900℃ | ±2.5℃ or ±0.75%t |

| Iron-constantan | J type | ≥Ф3mm | 500℃ | 600℃ | 0-600℃ | Not specified |

| Copper-Copper nickel | T type | ≥Ф3mm | 350℃ | 400℃ | <-200℃ | Not specified |

| -40-350℃ | ±1.0℃ or ±0.75%t | |||||

Thermal response time of thermocouple

| Sheath diameter(mm) | Thermal response time(s) | |

| Shell type | Insulation type | |

| 2.0 | 0.4 | 0.5 |

| 3.0 | 0.6 | 1.2 |

| 4.0 | 0.8 | 2.5 |

| 5.0 | 1.2 | 4.0 |

| 6.0 | 2.0 | 6.0 |

| 8.0 | 4.0 | 8.0 |

![]()

![]()