- Have any questions?

- +86 15953537010

- admin@wepower-electronic.com

Level measurement and control are of paramount importance in contemporary automation processes; indeed, there are two methodologies: contact measurement and non-contact measurement. Depending on the state of the medium, there exists measurement for liquid levels and measurement for solid (powder) levels.

Would now like to present a case involving non-contact level measurement for solids?Approximately two months ago, a distributor in Malaysia reached out to inquire whether we possessed an effective instrument for measuring the level of the nutshell silo? as he had visited a customer who expressed dissatisfaction with their current level measurement solution—the ultrasonic level meter—which had failed to function for several days, leaving them unaware of the underlying reason .

We requested images and videos of the medium and silo from this distributor, and we inquired as to whether there was any stirring occurring within the silo. Since the silo height is approximately 10 meters, we informed them that the primary reason was that their installed ultrasonic level meter is only good at measuring liquid levels, primarily for water, and that we do not recommend contacting type level instruments like guided wave radar level meters or contacting level switches (fork level switches, rotary level switches), which only measure points in time.

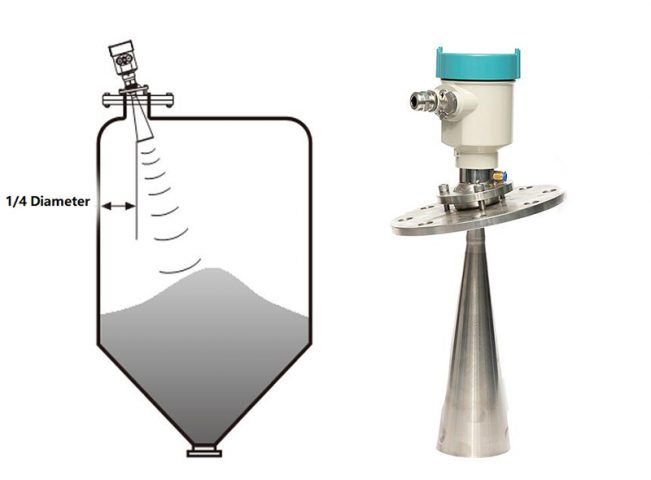

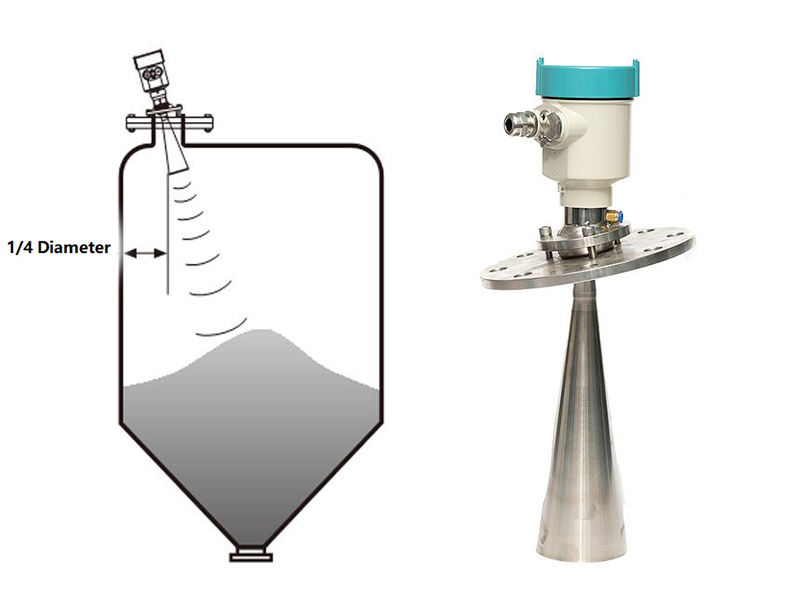

We ultimately suggested our WERD803-26G non-contact radar level meter based on the end user’s information; this model is also strongly suggested because there is not stirring device inside the silo .The technical rationale for equipping the universal swiveling flange with a solids nutshell medium is as follows:

The end customer has accepted our proposal for the radar level meter for their 10-meter silo and has placed an order promptly. Following installation, the end customer expressed considerable satisfaction with the high accuracy and stability of the device; they no longer need to worry and can now concentrate solely on their regular production.When there is a material pile, the antenna should be aligned vertically with the solids material surface. If the material surface is uneven and the pile angle is large, a universal flange must be used to adjust the angle of the horn so that the horn is aligned with the material surface as much as possible. (Due to the problem of echo attenuation and even loss of signal due to inclined solid surface)

Above all, the improper selection of instruments can not only hinder successful measurement but also result in wasted time and costs. Please do not hesitate to contact us upon reading this article; simply submit your inquiry to Wepower Electronic. We are a reliable and trustworthy authority in level measurement, and our objective is not to sell you our products, but to ensure that our level measuring devices are well-suited to your needs. Even if we do not have products that meet your requirements, we will provide you with appropriate suggestions.