- Have any questions?

- +86 15953537010

- admin@wepower-electronic.com

- Home

- Tempereaure Measurement

- Thermocouple Sensor

- K Type Sheathed Thermocouple

K Type Sheathed Thermocouple

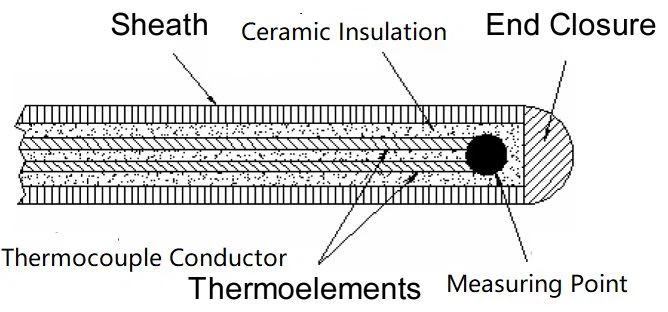

The wires of a K type sheathed thermocouple are insulated and implanted in a high-density ceramic compound, often magnesium oxide, before being covered in a metal sheath, as illustrated below.

![]()

The wires of K Type Sheathed Thermocouple are insulated and implanted in a high-density ceramic compound, often magnesium oxide, before being covered in a metal sheath, as illustrated below.

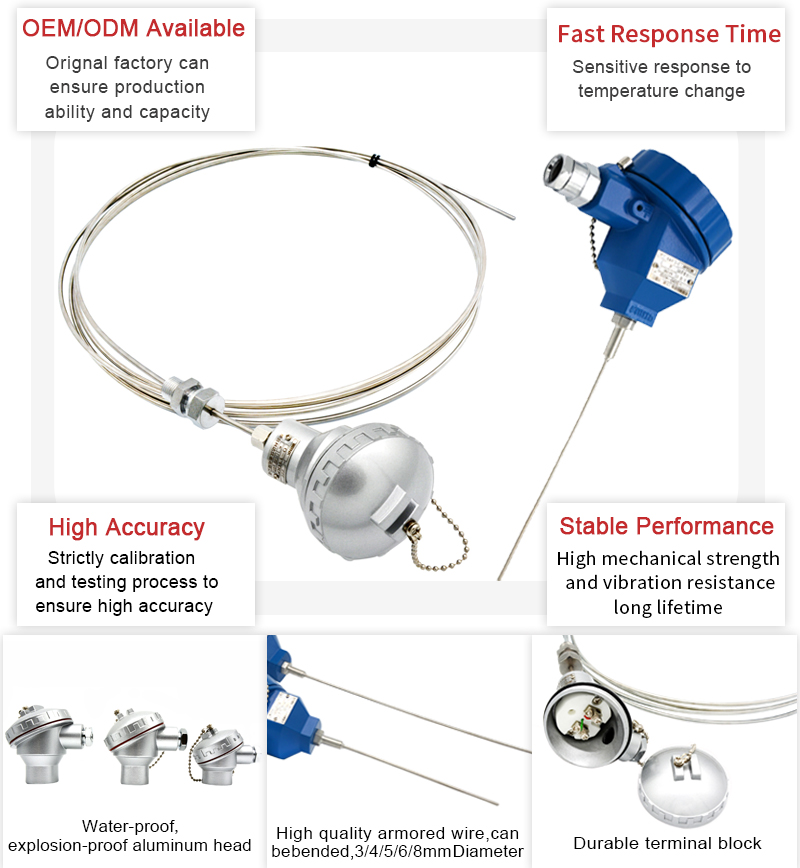

Sheathed thermocouples feature a protective sheath with a diameter of Φ1.5~Φ8 mm that shields the thermocouple wire. They are flexible, resistant to high pressure, have a quick thermal response time, and have a long operational life. In a variety of production processes, K type sheath thermocouples are used extensively because they can directly monitor the temperature of liquids, vapors, gas mediums, and solid surfaces in the 0–950 °C range. As a temperature sensor, thermocouple is usually used with display instruments, recording instruments and signal conditioners. Sheath thermocouple also can be used as a temperature sensing element for assembly thermocouple.

Parameters:

S/E/K/J/T type thermocouple temperature range and accuracy

| Category | Types | Sheath diameter | Normal working temperature | Highest working temperature | Allowable deviation | |

| Measuring range | Permissible deviation | |||||

| Platinum Rhodium 10 – Platinum | S type | ≥Φ3mm | 1100℃ | 1300℃ | 0~1300℃ | ±2.5℃ or ±0.75%t |

| Nickelchromium – Copper nickel | E type | ≥Φ3mm | 600℃ | 700℃ | 0~700℃ | ±2.5℃ or ±0.75%t |

| Nickel chromium – Nickel silicon | K type | ≥Φ3mm | 800℃ | 950℃ | 0~900℃ | ±2.5℃ or ±0.75%t |

| Iron – constantan | J type | ≥Φ3mm | 500℃ | 600℃ | 0~600℃ | Not specified |

| Copper – Copper nickel | T type | ≥Φ3mm | 350℃ | 400℃ | <-200℃ | Not specified |

| -40~350℃ | ±1.0℃ or ±0.75%t | |||||

Thermal Response Time Of Thermocouple

| Sheath diameter (mm) | Thermal response time (s) | |

| Shell type | Insulation type | |

| 2.0 | 0.4 | 0.5 |

| 3.0 | 0.6 | 1.2 |

| 4.0 | 0.8 | 2.5 |

| 5.0 | 1.2 | 4.0 |

| 6.0 | 2.0 | 6.0 |

| 8.0 | 4.0 | / |

![]()

![]()

![]()