- Have any questions?

- +86 15953537010

- admin@wepower-electronic.com

- Home

- Level Switch

- Vibration Fork Level Switch

- Vibrating Liquid Level Switch

Vibrating Liquid Level Switch

The vibrating liquid level switch causes the vibration of the piezoelectric crystal to cause its vibration. When subjected to material damping, the amplitude is sharply reduced and the frequency and phase change significantly.

![]()

Vibrating Liquid Level Switch is suitable for chemical, pharmaceuticals, feed, environmental protection, water treatment and other manufacturing and processing industries.

What Is The Working Principle Of Vibrating Liquid Level Switch?

The Vibrating Liquid Level Switch causes the vibration of the piezoelectric crystal to cause its vibration. When the fork of the vibrating liquid level switch is in contact with medium, the frequency and amplitude of the tuning fork will change. These changes of the tuning fork level switch of the tuning fork will be detected and processed by an intelligent circuit and converted into a switch signal.

What Are The Features Of Vibrating Liquid Level Switch?

- With automatic learning function, through the button, without calibration

- All metal structure, strong and durable; Not moving parts ,maintenance-free

- The fork body has a large vibration amplitude, which can reach more than 10mm, which can shake off the low-viscosity local hanging material on the induction rod to prevent mis-operation

- Compact type , small product dimension with light weight, much popular for the places with limit installation space

- Run a real impact by free flow, turbulence, bubbles, foam, vibration, solids content, coating, liquid properties and product changes

- Do not require calibration and installation procedures

- Polarity insensitive and short circuit protection

- The use of industry-standard plug / socket connector

| Measure Medium | Liquid |

| Vibrational Frequency | 350/1000HZ |

| Accuracy | ±2mm |

| Fork Length | 40mm or 100mm |

| Measuring Length | 40-1000mm |

| Ambient Temperature | -30-80℃ |

| Operation Temperature | -30-150℃ |

| Repeatability | ±2mm |

| Indication Method | LED |

| Power Supply | 24V DC |

| Power | 1 W |

| Signal Output | SPDT/PNP/NPN/NAMUR |

| Maximum Load | SPDT(5A); PNP/NPN(350mA) |

| Body Material | Stainless steel |

| Pressure Range | -98KPa-3MPa |

| Wetted material | SS304/SS316 |

| IP Grade | IP67 |

| Process Connecting | Thread, Tri-clamp |

| Electrical Interface | Hersman Joint / Aviation Joint |

![]()

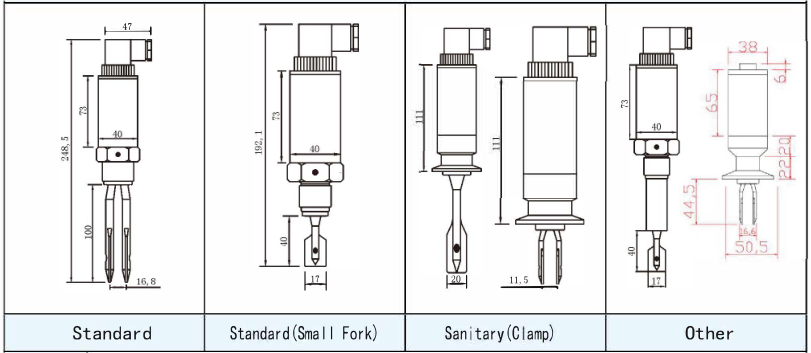

Dimension

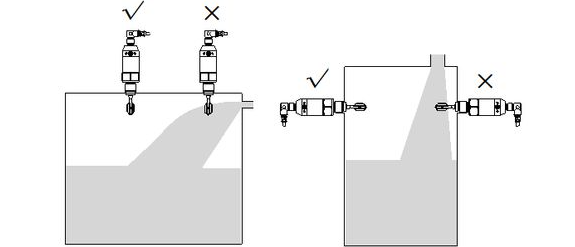

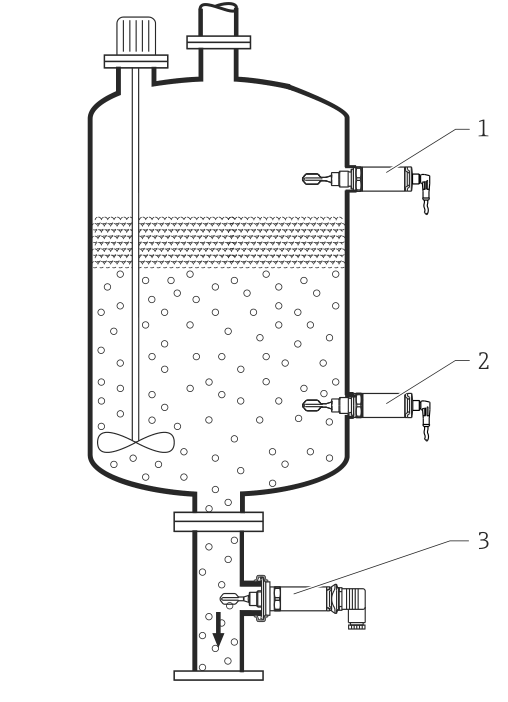

Installation Guidance

![]()

![]()

| Model Selection | |||||||

| WPX503 | Vibrating Fork Switch | ||||||

| / | Code | Product Type | |||||

| A | Standard | ||||||

| B | High Temperature | ||||||

| C | Sanitary | ||||||

| / | Code | Insertion Length | |||||

| 01 | 40mm | ||||||

| 02 | 100mm | ||||||

| 03 | Extended 100mm~3000mm Available | ||||||

| 04 | Cable Type Extended Split 1~100m Available | ||||||

| / | Code | Power Supply | |||||

| D | 24V DC±10% | ||||||

| / | Code | Material | |||||

| 1 | SS 304(Standard) | ||||||

| 2 | Ss316 | ||||||

| 3 | Other Material (Please Remark) | ||||||

| / | Code | Process Connecting | |||||

| G | G1″Thread(standard) | ||||||

| T | 1″NPT Thread | ||||||

| C | Customer Other Request (Please Note Spec) | ||||||

| F | Flange Connecting (Please Note Flange Spec) &Standard) | ||||||

| / | Code | Other Parameters | |||||

| A | Normal Temperature: ℃ | ||||||

| B | Normal Pressure: Kpa | ||||||

| C | IP Grade:IP66 | ||||||

| D | Explosion:ExdⅡCT6 | ||||||

| E | Max Temperature:℃ | ||||||

| F | Max Pressure:Kpa or Mpa | ||||||

| () | Customer Other Request | ||||||

| / | |||||||

| 503 | A | 01 | D | 1 | G | AB (Example ) | |