- Have any questions?

- +86 15953537010

- admin@wepower-electronic.com

- Home

- Level Switch

- Vibration Fork Level Switch

- Fork Level Sensor

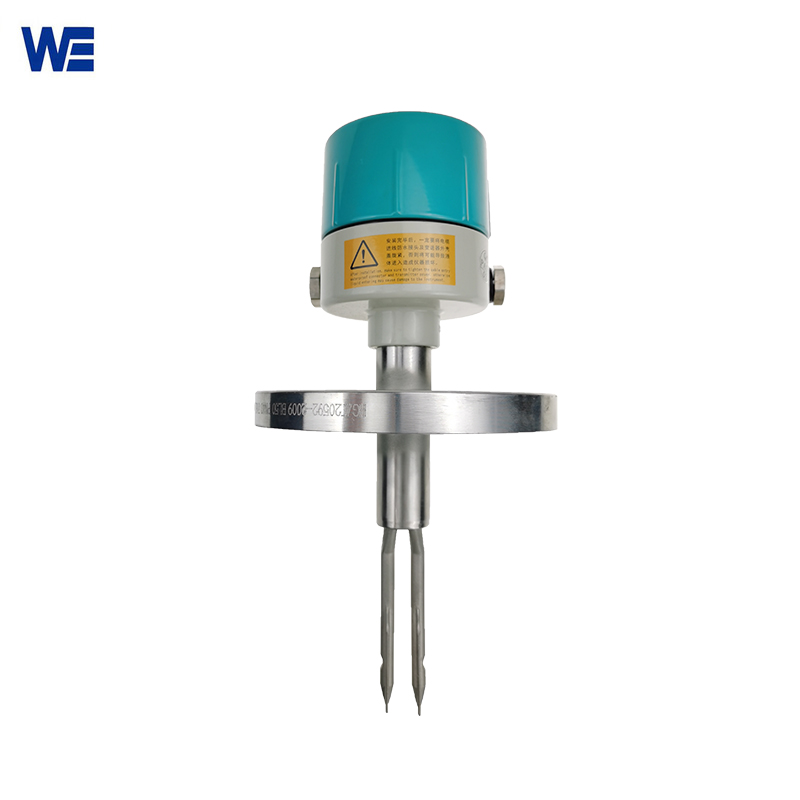

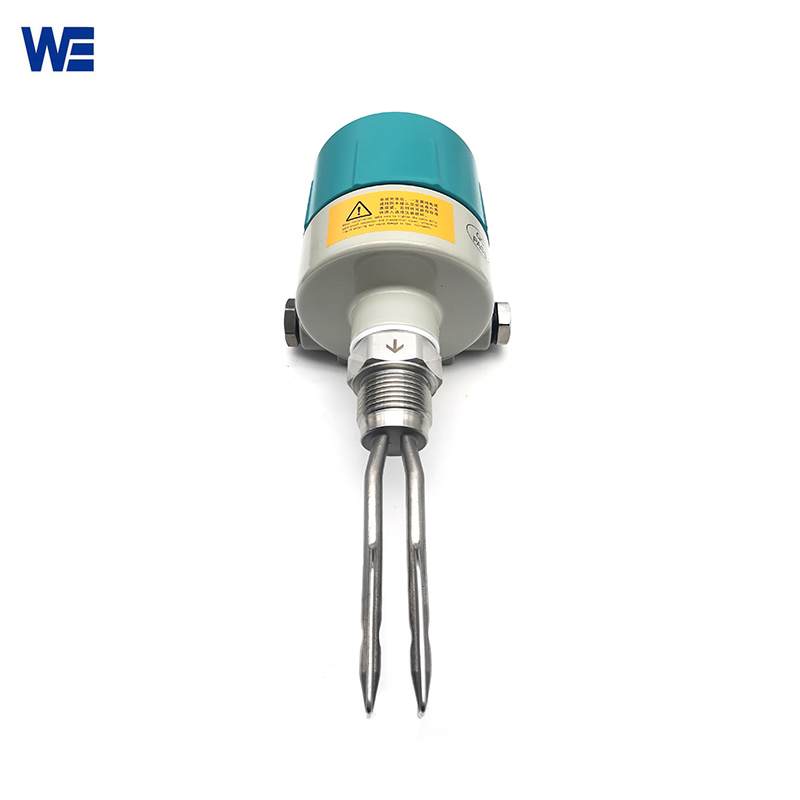

Fork Level Sensor

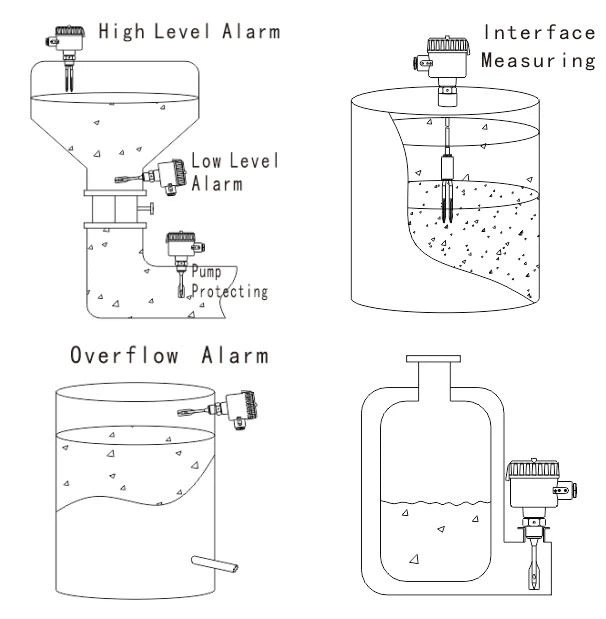

Fork level sensor is widely used in fields such as: Solid materials: rice, milk powder, sugar, salt, laundry, dyes, cement, stone powder, plastic particles, Liquid medium: water, mud, dye, oil, milk, wine, beverage, etc.

![]()

What Are The Advantages Of Fork Level Sensor?

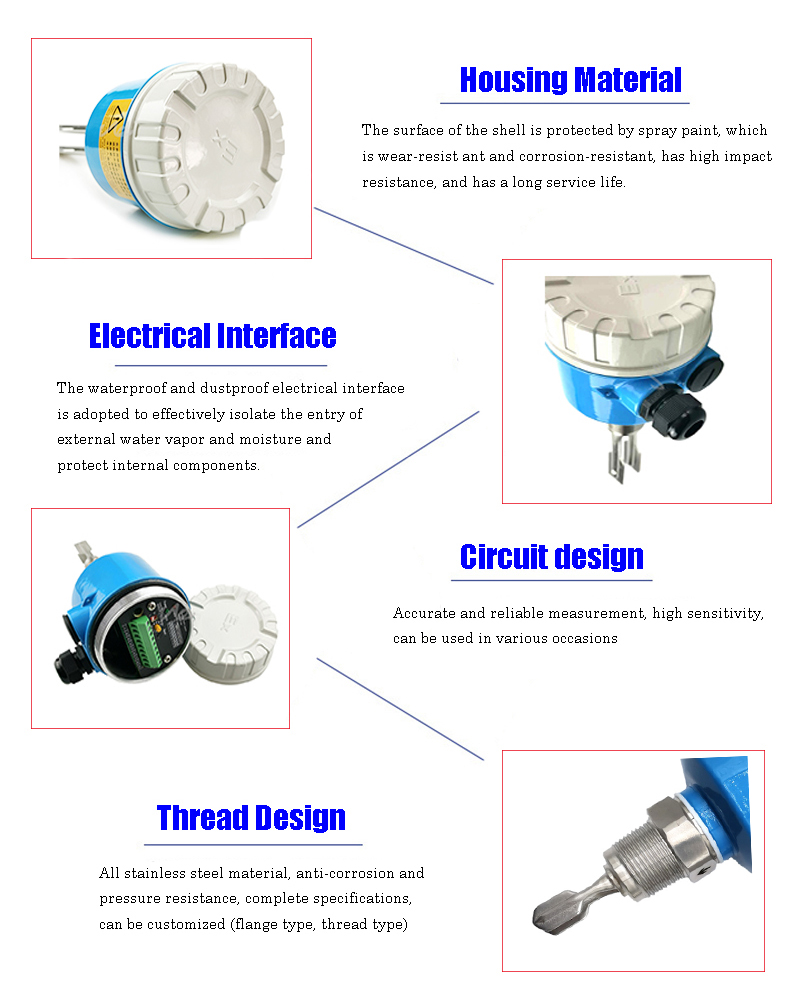

WPX series Fork Level Sensor can monitor, control and alarm the high and low levels of the tank, suitable for various liquids, powders, and granular solids. Fork level sensor is practical and simple, reliable in operation, and highly adaptable.

Vibrating level switch is basically maintenance-free. It is equipped with three input modes (DC 24V, AC 220V);there are three process connecting types : thread , flange , tri-clamp actually that thread connecting are the most used connecting method.

| Fork Level Sensor | |

| Medium | liquid, powder or granular solid |

| Measured medium density: | solid ≥0.1g/cm3 Liquid ≥0.7g/cm3 |

| Measured solid particle size: | ≤10mm |

| Maximum liquid viscosity: | <1000mm2/s |

| Measured medium repose angle: | ≥200 |

| Fork Length | 40mm/100mm |

| Temperature | Medium temperature range: -20°C~150°C |

| Ambient temperature: -20°C~80°C | |

| Pressure range: | ≤1MPa |

| Product Material | Housing Material: Die Cast Aluminum Alloy Or Compact Stainless Steel |

| Fork body material:SS304/SS316 | |

| Explosion-proof grade: | DIIBT4 |

| Housing protection class: | IP65 |

| Process Connection: | 1″ NPT thread;3/4″ thread,1/2″ thread,G1″ thread etc Flange (user selected) |

| Supply voltage: | DC24V; AC220V 50HZ |

| Output signal: Relay output: | 5A 220V AC ; 3A 24V DC |

| Power consumption: | ≤ 2W |

| Vibration frequency: | 300±50Hz |

![]()

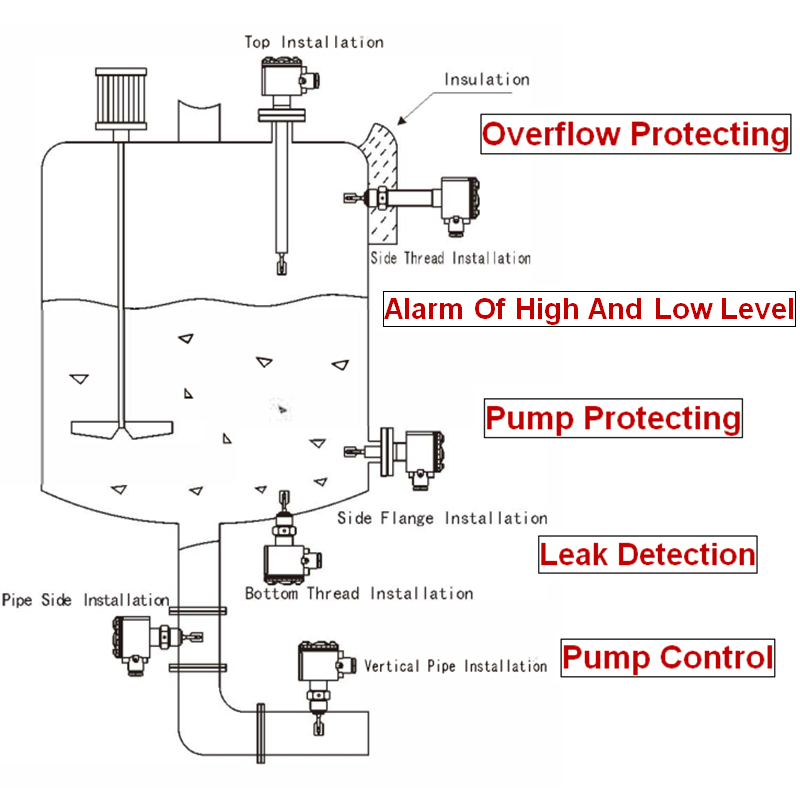

Installation Guidance

![]()

![]()