- Have any questions?

- +86 15953537010

- admin@wepower-electronic.com

- Home

- Level Meter

- Magnetostrictive Level Meter

- Magnetostrictive Oil Level Meter

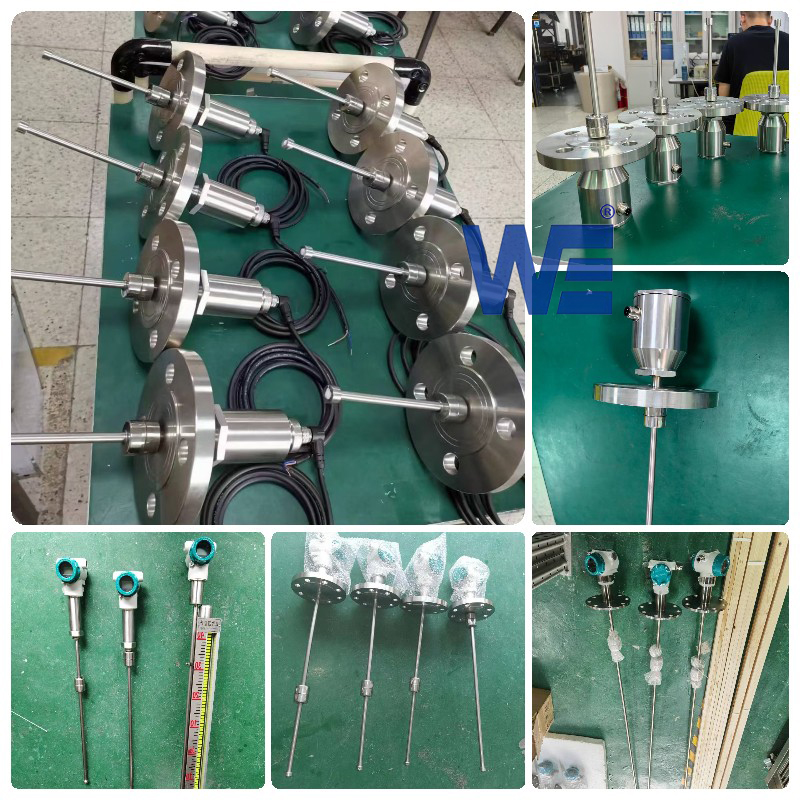

Magnetostrictive Oil Level Meter

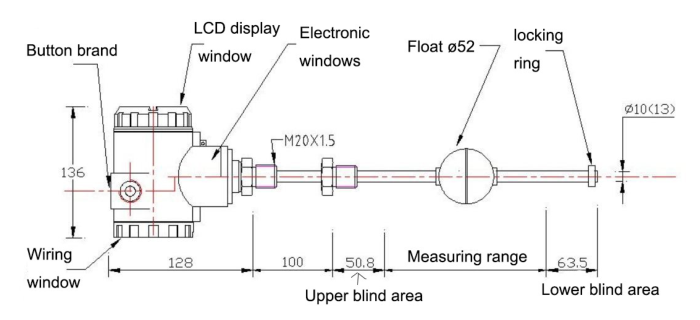

The Magnetostrictive Oil Level Meter is designed based on the principle of magnetostriction .It is composed of a sensitive waveguide wire, a waveguide , a moveable magnet, and electronic components that emit electrical pulse signals and receive return signals.

![]()

Working Principle & Benifits Of Magnetostrictive Oil Level Meter:

The Magnetostrictive Oil Level Meter is designed based on the principle of magnetostriction .Magnetostrictive Oil Level Meter is composed of a sensitive waveguide wire, a waveguide , a moveable magnet, and electronic components that emit electrical pulse signals and receive return signals. When the pulse microwave generator in the electronic probe generates ,the electric pulse is transmitted along the waveguide wire in the steel pipe , the electric pulse is accompanied by a circular magnetic fields perpendicular to the waveguide wire and transmits along the waveguide wire at the speed of light .By measuring the time difference between the power generation pulse and the induction pulse generated by the torsion wave return, the measured liquid level can be accurately calculated.

High precision, good stability, widely used in petroleum diesel oil tank industry, small linear error, direct use without debugging, can withstand high pressure and maximum pressure can reach 10Mpa, not affected by dielectric constant. Magnetostrictive Oil Level Meter can measure the oil-water interface, the customer only needs to provide the oil density, LCD display, and adjust the range on site. Anti-corrosion models are used in chemical and other industries. Our Magnetostrictive Oil Level Meter have passed the explosion-proof and SIL3 certificates, please feel free to consult and purchase.

Features of Magnetostrictive Oil Level Meter:

▲Widely used in high temperature and high pressure liquid and corrosive liquid environment

- The maximum measuring distance of the rod probe is 6 meters, and the temperature range -40-400℃;

- The maximum measuring distance of cable probe is 20 meters;

- For corrosive liquids, Teflon, PTFE probes and floats are used;

- For stratified liquids, the boundary and liquid levels can be measured simultaneously

▲High precision, ±0.5mm or ±1mm; High resolution, fast response

▲A variety of data output options:

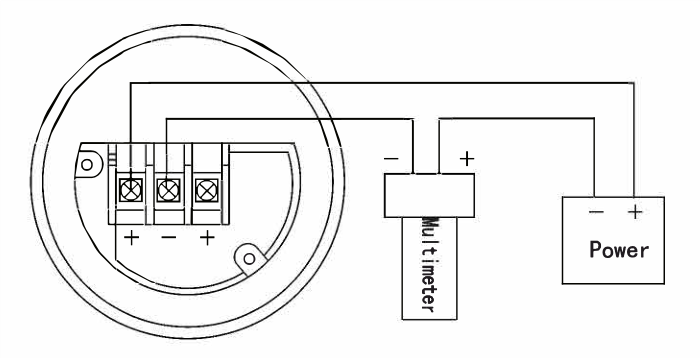

- HART (standard) 4-20mA analog signal

- PROFIBUS PA

- Foundation Fieldbus (FF)

▲The float magnet adopts imported magnets with long service life

▲ A variety of output methods are available

▲With reverse polarity protection function

▲Anti-lightning, anti-radio frequency interference, easy installation, no need for regular calibration and maintenance; the Magnetostrictive Level Meter are designed and certified in accordance with explosion-proof requirements. It is suitable for accurate measurement of process vessels and storage vessels in petroleum, chemical, electric power, steel, food, pharmaceutical and other industries.

![]()

![]()

| Product | Magnetostrictive Oil Level Meter (WPX 901) |

| Power Supply | 24V±2.4V. DC |

| Working Temperature | Electronic Part:-40 ℃ ~ + 80℃ |

| Measuring Rod :-40℃ ~+110℃ | |

| Range | Hard Rod:150mm~7000mm,Soft Rod:Max20000mm |

| Output Signal | 4~20mA;0~5V;0~10V;±5V;±10V;RS-485 |

| Linear Error | Better±0.05%FS;When Rangeless than 300mm,Error less than150μm |

| Repeatability | Better ±0.002%FS |

| Output Temp Drift | 50ppm/℃ |

| Power Consumption | ≤50mA |

| Output Ripple Current | ≤20mV |

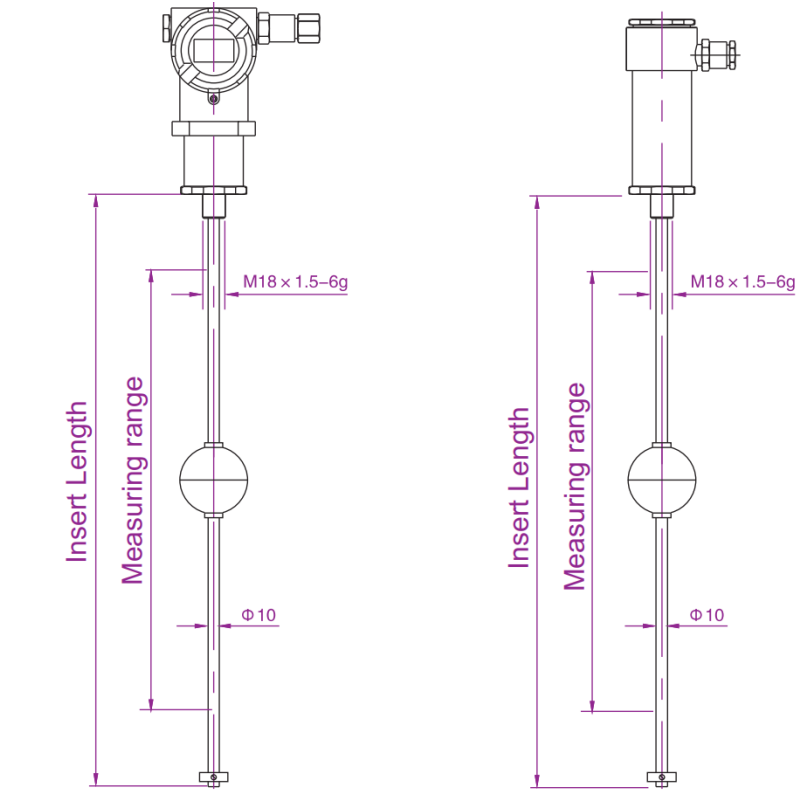

| Fade Zone | Fade Zone : Soft Rod :100mm(Upper ,300mm(Under) |

| Hard Rod:51mm (Upper),36mm(Under);Can Be Changed According To User’s Requirement | |

| Load Capacity | 4~20mA Output:Load Capacity ≤500Ω |

| 0~5V,0~10V Output :Min Controller Load≥5kΩ | |

| Measuring Rod Material | 0Cr18Ni9、1Cr18Ni9Ti Or Customized |

| Housing Material | 1Cr18Ni9Ti |

| Wiring | 1.Shielded Cable Connection,Standard Length 1.5m(Can be Changed ) |

| 2 Aviation Plug Connection | |

| 3.Terminal Connection | |

| Float Material | 0Cr18Ni9、SS316、Nitrile |

| Process Connecting | Thread,Connecter Head,Positioning Ring , Suspension or Customized |

| IP Grade : | IP65 |

![]()

![]()

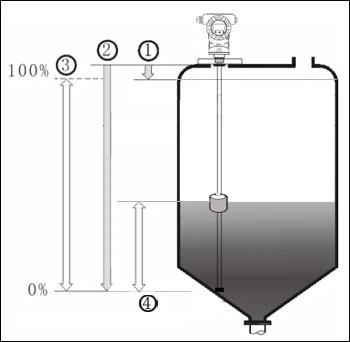

Before installation, use a dipstick to check whether the actual installation height of the oil tank (2) is consistent with the length of supply, The magnetostrictive level sensor is 50-100mm under connecting as the measurement blind zone, generally there is no reading, open the box to check the list of accessories, check whether there is transportation Damage

Use the bypass pipe to install when the liquid level in the container is unstable

Installation Steps

- Remove the flange at the inspection hole of the oil tank

- Insert the measuring rod into the mounting hole of the mounting flange

- Install the liquid level float, interface float and locking ring on the measuring rod in turn

- Insert the probe into the measuring hole

- After placing the probe on the bottom of the tank, lift it up so that the end of the measuring rod is 2~10mm away from the bottom of the tank to prevent the measuring rod from bending

![]()