- Have any questions?

- +86 15953537010

- admin@wepower-electronic.com

- Home

- Level Meter

- Magnetostrictive Level Meter

- Magnetostrictive Storage Tank Level Sensor

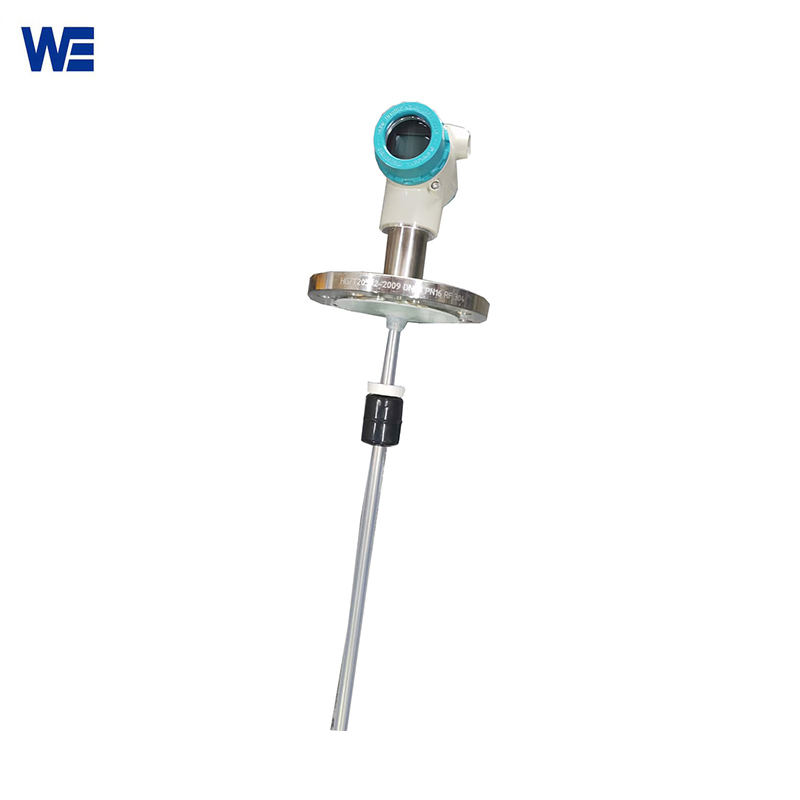

Magnetostrictive Storage Tank Level Sensor

Magnetostrictive storage tank level sensors are primarily used to check the liquid level in the tank. Wepower magnetostrictive storage tank level sensor features more reliable measurement findings, a longer service life, a compact structure, and excellent environmental adaptability.

![]()

What Are The Advantages Of The Magnetostrictive Storage Tank Level Sensors?

Magnetostrictive Storage Tank Level Sensors are used to measure high water solubility liquids that are free of contaminants. One of the benefits of magnetostrictive storages tank level sensors is their adaptability. Magnetostrictive storage tank level sensors can be used in a wide range of tanks and vessels, including storage tanks, mixing tanks, and reactor vessels. A magnetostrictive storage tank level sensor can also be used for interface detection, in which the transmitter measures the level at which two immiscible liquids come into contact.

Troubleshooting Magnetostrictive Storage Tank Level Sensor :

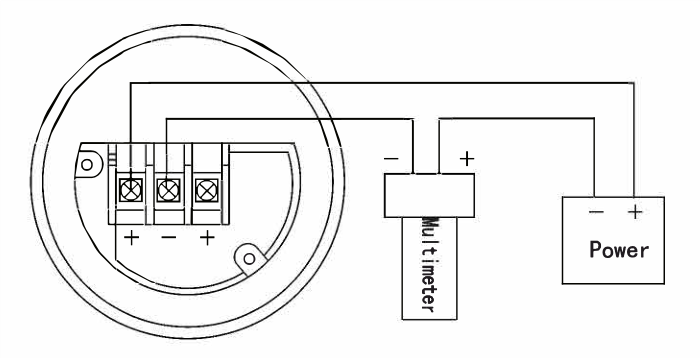

▲When using the magnetostrictive storage tank level sensor, the current output is 0mA. The possible cause of the fault is incorrect wiring. Wire correctly according to the instructions.

▲During the use of magnetostrictive storage tank level sensor, unstable current output may be caused by insufficient power supply or problems in the adjustment process. It is necessary to increase the power supply power or recalibrate the instrument according to the actual situation.

![]()

![]()

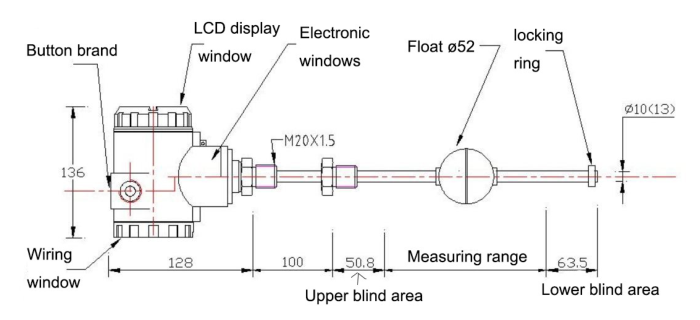

| Product | Magnetostrictive storage tank level sensor |

| Measuring range | 100-5000mm |

| Wetted material | AISI304, AISI316, PTFE etc. |

| Measurement field | Water, aqueous solution, beverages, food production, beverage production, chemical reagent production, petrochemical industry, crude oil storage, etc. |

| Medium | specific gravity ≥0.5g/cm3 and viscosity 1.25St |

| Accuracy | :≤±0.1%FS or 1um, whichever is the maximum |

| Power supply | DC12-36V |

| Output | two-wire 4-20mA+HART (optional) |

| Measurement display resolution | 0.3mm |

| Nonlinearity | <±0.05%FS |

| Hysteresis | ≤±0.002%FS |

| Temperature | -40-85°C (special instruction are required if it exceeds 85°C) |

| Pressure | 0-1Mpa (special indication is required when exceeding 1Mpa) |

| Explosion-proof | EXiaⅡCT4 intrinsically safe type |

| Junction box protection level | IP65 |

| Magnetic float ball | Standard ø76 special supply ø48, ø51, ø120,

ø145 or user’s choice. Float height F: ø48, is 55, ø51 is 60, ø76 is 80, ø120 is 125, ø145 is 150 (mm) |

![]()

![]()

![]()

| Ordering Information Sheet | ||||||

| Magnetostrictive Level Sensor | ||||||

| CODE | TYPE | |||||

| A | Standard | |||||

| B | High Temp | |||||

| C | Sanitary(Hygienic) | |||||

| / | CODE | Length | ||||

| 01 | 1000mm(Standard ) | |||||

| 02 | Tube Extension 1000mm~3000mm | |||||

| 03 | Cable Extension Split 1~20000mm | |||||

| / | CODE | Power Supply | ||||

| D | 24V DC±10% | |||||

| / | CODE | Material | ||||

| 1 | SS304(Standard )) | |||||

| 2 | SS316 | |||||

| 3 | Anti-corrosive ,With PTFE Coating | |||||

| / | CODE | Process Connecting | ||||

| G | G1”Thread (Standard)) | |||||

| T | 1”NPT Thread | |||||

| C | Other ( Customer Remark ) | |||||

| F | Flange(Please Remark Flange Spec) | |||||

| / | CODE | Other Parameters | ||||

| A | Normal Temp: ℃ | |||||

| B | Normal Pressure : Kpa | |||||

| C | IP Grade:IP65 | |||||

| D | Explosion-proof :ExdⅡ CT5 | |||||

| E | Max Temp: ℃ | |||||

| F | Max Pressure: Kpa or Mpa | |||||

| () | Other Request | |||||

| / | ||||||

| A | 01 | D | 1 | G | AB (EXAMPLE ) | |