- Have any questions?

- +86 15953537010

- admin@wepower-electronic.com

- Home

- Level Meter

- Magnetic Level Indicator

- Magnetic Type Level Gauge

Magnetic Type Level Gauge

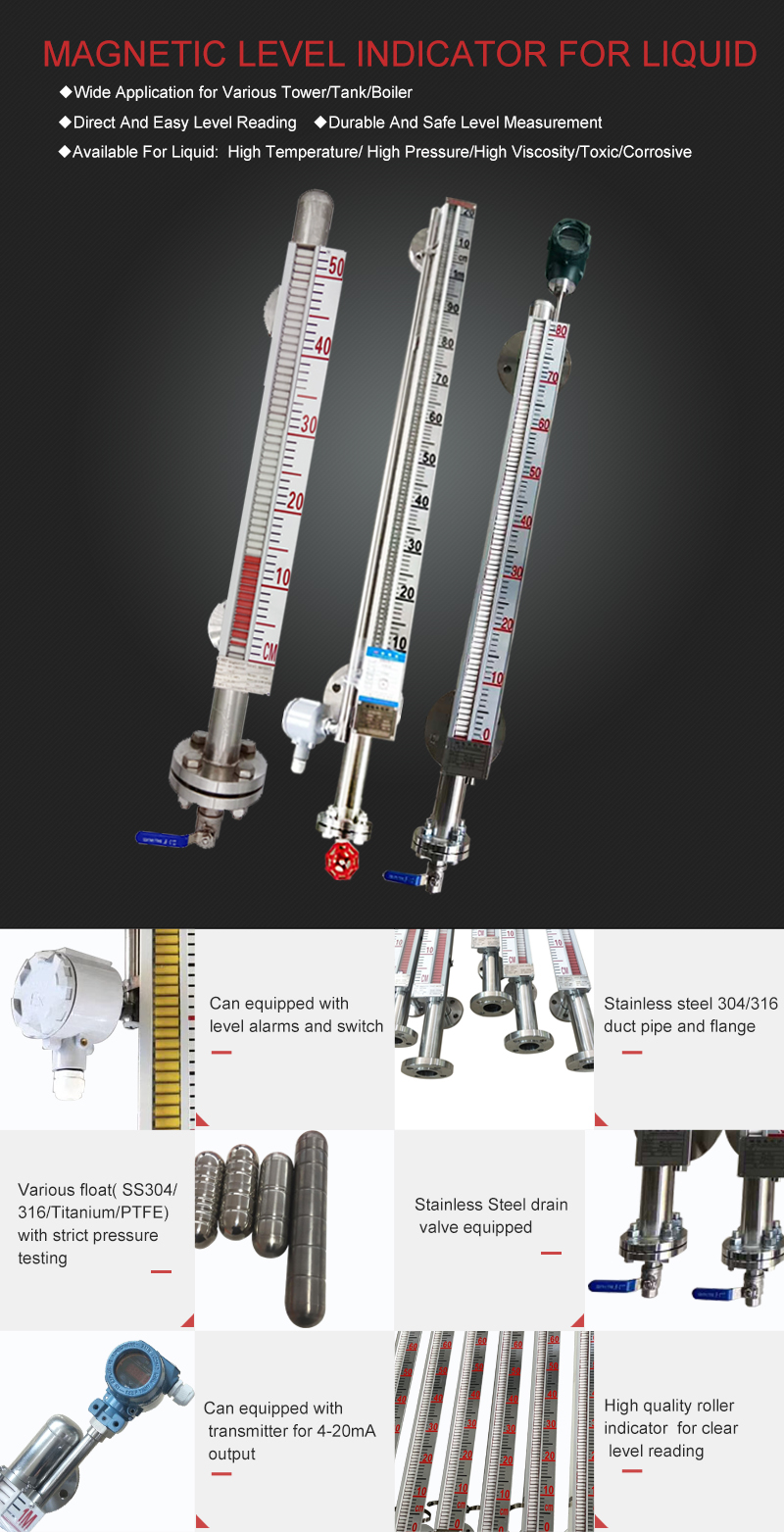

Magnetic type level gauge is a professional liquid level gauge widely used for many applications. Wepower magnetic type level gauge is simple to install and easy to observe directly.

![]()

Magnetic Type Level Gauge is a standard explosion proof water & oil level measurement indicator. Magnetic type level gauges are commonly used in chemical oil processing plants and water treatment companies. Because of the unique design of magnetic type level gauges, level gauges can withstand the pressure of long-term operation, and are also very time-saving and labor-saving in maintenance.

The display transparent screen of our company’s magnetic type level gauge is made of high-performance anti-drop and high-temperature resistant glass in China. It is not easy to fog or burst in high temperature, high pressure or low temperature environments. The conduits of the Magnetic level gauge are made of thick heat-resistant and rust-resistant aluminum alloy conduits. The inner cavity of the catheter is smooth, and the float in the catheter moves smoothly and is not easy to wear.

How Does The Magnetic Flap Work?

After the liquid enters the tank, the liquid in the conduit on the magnetic flap level gauge and the liquid in the tank tend to be at the same level. Inside the measuring conduit is a free-floating “float”. This magnetic float will bring changes to the panel close to the measuring tube. The small red and white squares in the panel are magnetic flip columns. When these red and white squares are affected by an external magnetic force, they flip. Assuming the white panel is the initial state, the panel changes from white to red, indicating that the liquid level in the measured tank rises; red changes to white, indicating that the liquid level in the tank drops. Generally speaking, the working principle of the magnetic flap is like this.

![]()

![]()

| Measuring medium: | water, hydrochloric acid, strong alkali, ammonia water |

| Measuring range: | 300-15000mm |

| Operating temperature: | -40-480°C |

![]()

| UHZ Magnetic Liquid Level Gauge | ||||||||

| / | A Side Mounted B Top Mounted |

Installation Type | ||||||

| / | 1 Basic Type 2 Anti-corrosive 3 Jacket Type 4.High Pressure &Pressure |

Type | ||||||

| / | C 0.6MPa D 1.6MPa E 2.5MPa F 4.0Mpa G 6.4Mpa H More than 6.4MPA |

Working Pressure | ||||||

| / |

|

Optional | ||||||

| / | L= Measuring Range (For Side Mounted) | / | ||||||

| / | L1=Measuring Range (Top mounted 0~4000mm) | / | ||||||

| / | Medium Density ρ(g/cm3) | / | ||||||

| / | / | |||||||

| A | 1 | D | 1 | L=2500mm | L1=3000mm | ρ=0.8g/cm3 | Example | |

![]()

![]()

Wepower ensures comprehensive factory inspection and excellent after-sales service.

Wepower ensures comprehensive factory inspection and excellent after-sales service.