- Have any questions?

- +86 15953537010

- admin@wepower-electronic.com

- Home

- Pressure Measurement

- Pressure Transmitter(WE3051)

- Fluid Pressure Transmitter

Fluid Pressure Transmitter

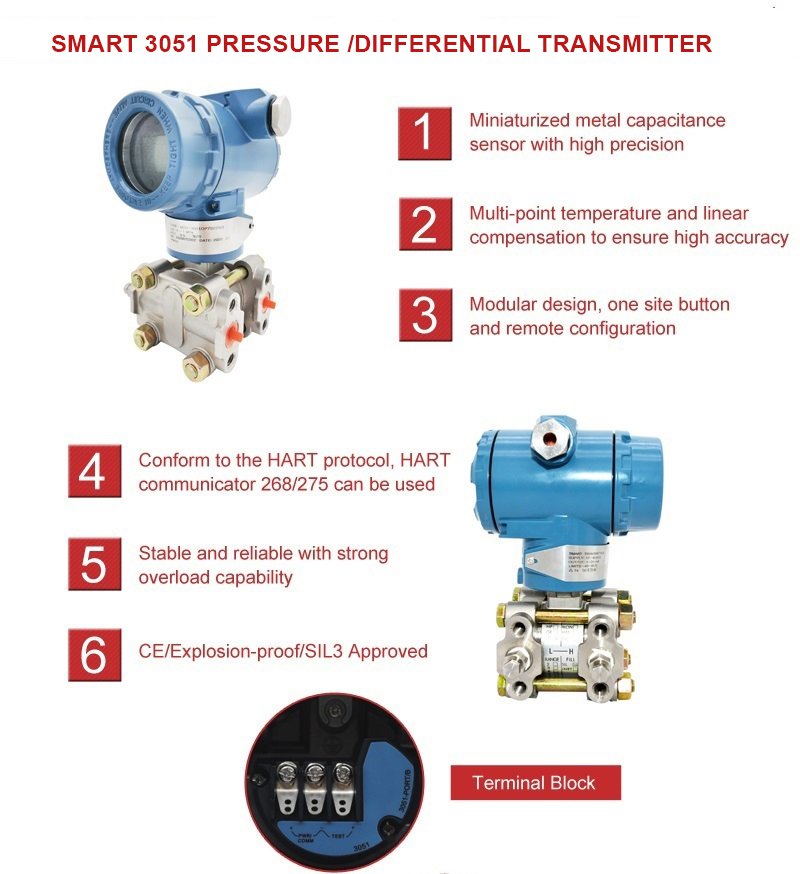

Fluid pressure transmitter plays important role in industrial automation field , the smart WE3051 Fluid pressure transmitter measure and convert pressure signal to PLC or DLC system for process control,monitoring and management .We are committed to provide correct ordering selection after we collect the measuring parameters.

![]()

Fluid pressure transmitter plays important role in industrial automation field , the smart WE3051 Fluid pressure transmitter measure and convert pressure signal to PLC or DLC system for process control,monitoring and management .The measurement error of the pressure transmitter is divided according to the accuracy level. Different accuracy corresponds to different basic error limits (expressed as a percentage of the full-scale output). In practical applications, selection should be made based on the control requirements of measurement errors and the principle of economical use. The smaller the range of the pressure transmitter, the more difficult it is to measure the pressure value, so please inform us of the specific parameter information before placing an order.

What is the Points of Selection Of Pressure Measuring Transmitters ?

- The selected pressure measuring point can reflect the true situation of the measured pressure.

- It should be selected in the pipe section where the medium to be measured flows in a straight line, and not in the pipeline bends, bifurcations, dead corners or other places where vortices are easy to form.

- When measuring the pressure of a flowing medium, the pressure point should be perpendicular to the flow direction.

- When measuring gas, the pressure point should be above the pipe so that there is no liquid in the pressure pipe.

- When measuring liquid pressure, the pressure point should be at the lower part of the pipe so that there is no gas in the pressure pipe.

- The installation location should strive to avoid vibration and high temperature effects.

![]()

| Sensor Type | Differential /Pressure Transmitters -Fluid Pressure Transmitter |

| Accuracy | ±0.1-0.2% |

| Medium | Liquids, steam and gas |

| Stability | 0.2% |

| Measuring Range | 0~1.5, 0~7.5, 0~37.4, 0~186.8, 0~690, 0~2068 |

| Explosion-proof Type | General type, Exd II C T6 Gb, Exia II C T6 Ga |

| Output Signal | 4-20mA DC, HART |

| Diaphragm Material | SS316L, Hastelloy C, SS316L |

| Diaphragm Fluids | Silicone oil, fluorine oil |

| Drain hole location | Rear face of process flange, Upper side of process flange, Lower side of process flange |

| Process Flange and Bolts | Stainless steel or carbon steel |

| Process flange O-ring material | Buna-N (NBR), Fluorine rubber (FKM) (not below -20 degrees Celsius) |

| Process Connections | NPT1/4 inner bolt |

| Static Pressure | 14Mpa (range2 =4Mpa; range3=7Mpa) /25Mpa/32Mpa |

| Power Supply | 9-32 V DC |

| Bracket | None, Tube mounted bend bracket (carbon steel), Wall mounted bracket (carbon steel), Tube mounted flat bracket (stainless steel), Wall mounted bracket (stainless steel), Tube mounted flat bracket (stainless steel) |

![]()

![]()

![]()

![]()

![]()

| Name | Specification code | Description | ||

| WE3051GP WE3051DP |

/ | Pressure Transmitter Differential Pressure Transmitter |

||

| / | 3 | (0.013-0.075)bar | ||

| 4 | (0.062-0.374)bar | |||

| 5 | (0.31-1.868)bar | |||

| 6 | (1.17-6.9)bar | |||

| 7 | (3.45-20.68)bar | |||

| 8 | (11.7-68.90)bar | |||

| 9 | (34.8-206.8)bar | |||

| 0 | (68.9-413.7)bar | |||

| Output Signal | E | analog type 4-20mA | ||

| S | 4-20mA, HART Protocol Digital Communication | |||

| Wetted Parts Material |

/ | Flange/Joint | Exhaust/Drain Valve | Diaphragm |

| 22 | Stainless Steel | Stainless Steel | 316L Stainless Steel | |

| 23 | Hastelloy C-276 | |||

| 24 | Tantalum | |||

| Mounting Bracket |

B1 | Tube-type Curved Bracket (Tube ODΦ50~Φ60) | ||

| B2 | Board- type Curved Bracket | |||

| B3 | Tube-type Straight Bracket (Tube ODΦ50~Φ60) | |||

| Display Header (optional) |

M2 | Linear Pointer Header (0~100% scale) | ||

| M3 | Square Root Instruction Header(0~100% scale) | |||

| M4 | LCD Header(0~100% linear display) | |||

| Process Flange | D | The liquid discharge / exhaust at the back | ||

| D1 | The liquid discharge / exhaust at the side top | |||

| D2 | The liquid discharge / exhaust at the side bottom | |||

| Flange Joint | J | “D-shaped” Joint with ” M20*1.5″ External thread | ||

| / | N | Joint with 1/2-14NPT taper pipe thread waist type | ||

Wepower Electronic is constantly in the lead for the greatest quality and service ! Contact us now!